AlphaFlo®

Ricambi pompa ghiaia

AlphaFlo® fornisce superbe parti di pompe per ghiaia Warman G&GH con retromarcia analogica

Il produttore e il fornitore di AlphaFlo® china alternano le dimensioni delle parti della pompa per ghiaia warman G e GH intercambiabili e materiali equivalenti.

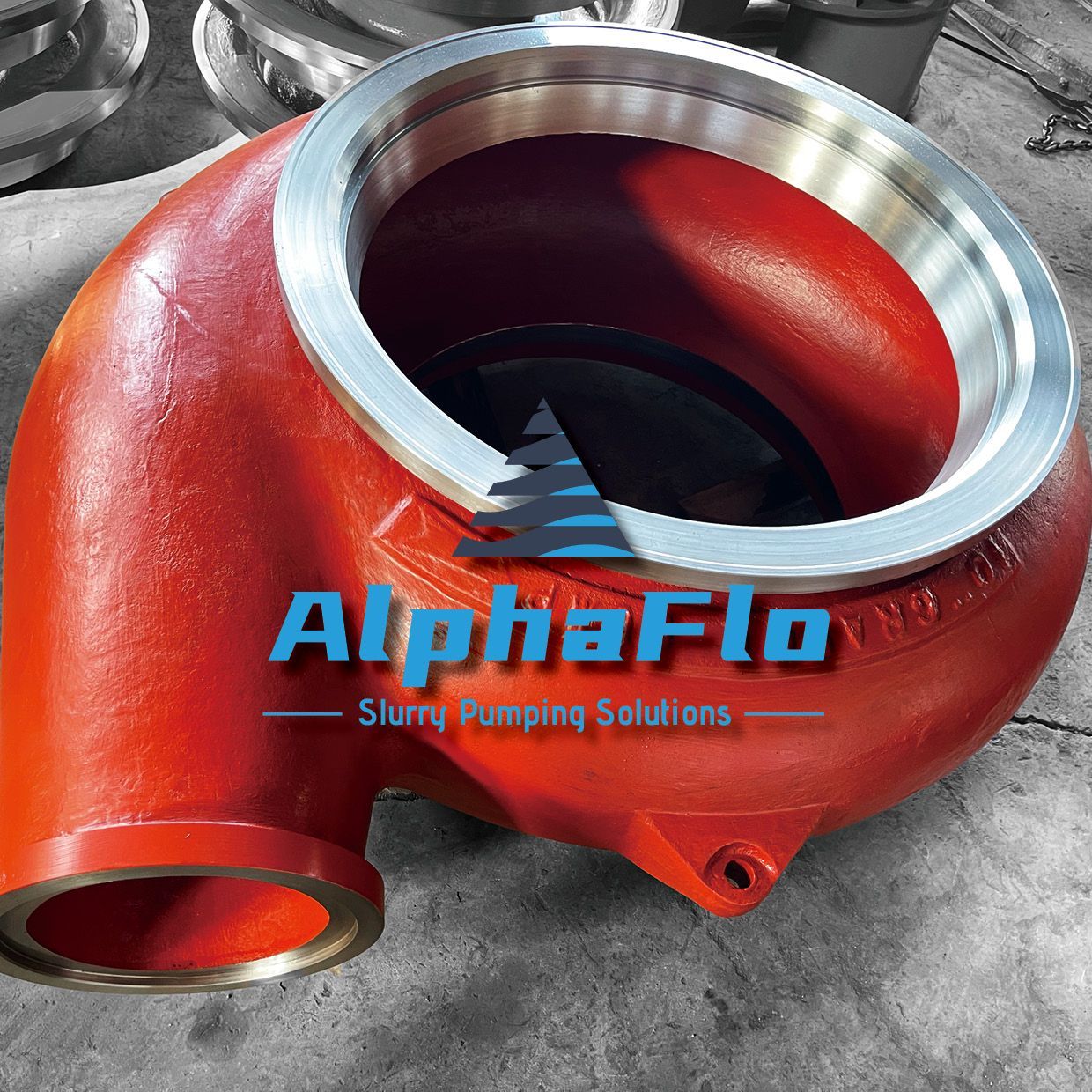

The G&GH range of Dredge and Gravel pumps is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

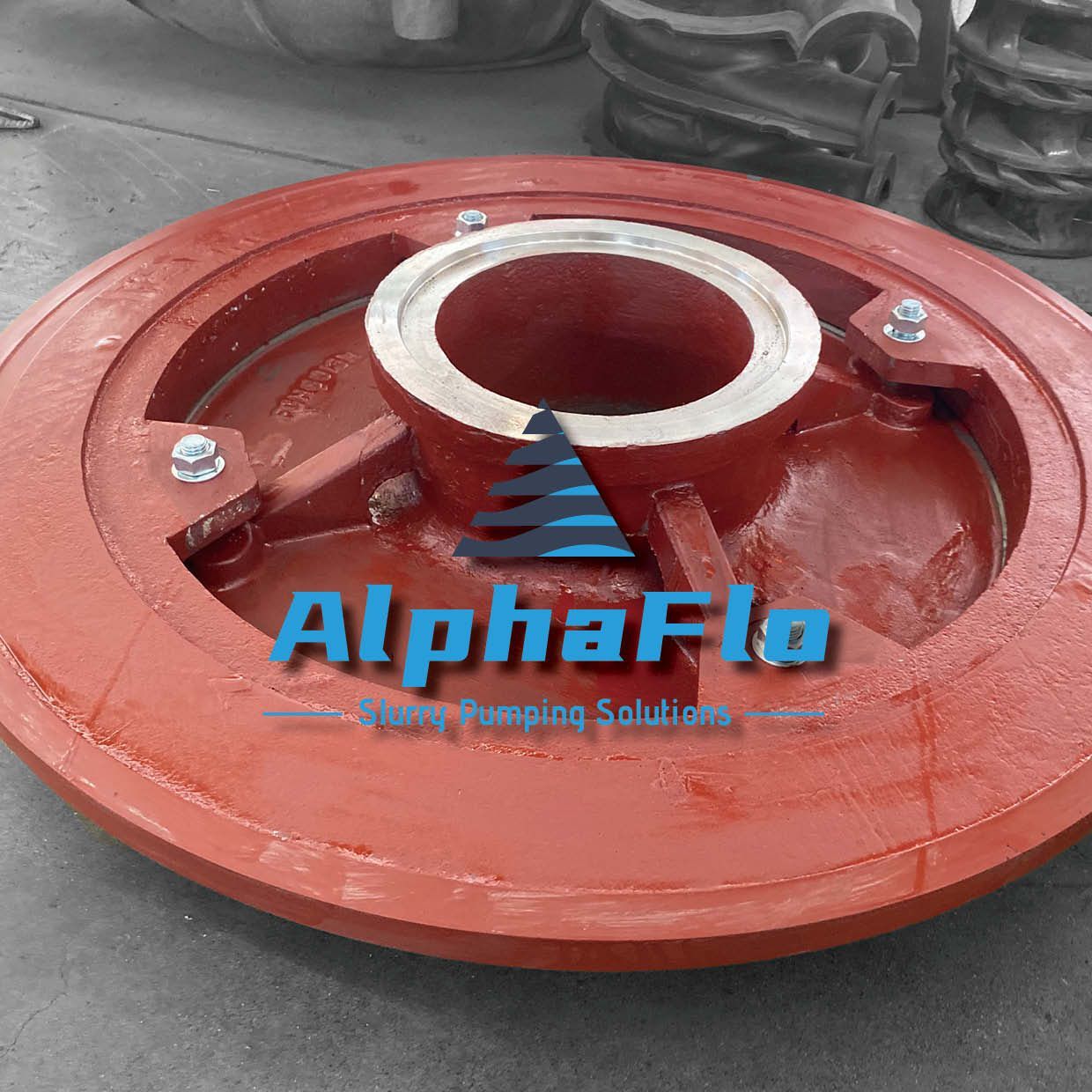

- The unique segmented clamp ring on larger size units and solid on smaller pumps, facilitates casing rotation to any angle, reducing the need for costly high wearing bends. Minimal maintenance is required.

- Impeller expulsion vanes reduce gland pressure and intrusion of high concentrations of solids in the gland area. Efficiency is maintained by minimising suction side recirculation.

- Specially designed and shaped impeller vanes allow the handling of extraordinarily large particles. The unique casing design and sealing vanes prevent abrasive solids intrusion at the sealing faces.

- The large, robust casing has been designed to reduce internal velocities resulting in minimum efficiency loss and improved casing wear life. The casing is made up of three components to reduce maintenance time and costs associated with a onepiece design. (Except the 6/4 DG which has two components)

- Heavy-duty grease lubricated taper roller bearing assemblies are fitted as standard. A rigid large diameter shaft with reduced overhang minimises deflection and vibration under all conditions ensuring trouble free operation.

| OEM WEIR | WARMAN | WARMAN |

|---|---|---|

| POMPA WARMAN | SERIE G | SERIE GH |

| POMPA WARMAN | POMPA PER GHIAIA | POMPA PER GHIAIA |

| POMPA WARMAN | 6X4 DG | 10X8 S-GH |

| POMPA WARMAN | 6X4 DD-G | |

| POMPA WARMAN | 6X6 ES | 12X10 TGH |

| POMPA WARMAN | 6X6 EEG | 16X14 TU-GH |

| POMPA WARMAN | 8X6 FA | 16X14 H-GH |

| POMPA WARMAN | 8X6 FF-G | 18X16 TU-GH |

| POMPA WARMAN | 8X8 FA | |

| POMPA WARMAN | 8X8 FF-G | 18X16 H-GH |

| POMPA WARMAN | 10X8 FA | |

| POMPA WARMAN | 10X8 FF-G | |

| POMPA WARMAN | 10X8 SGR | |

| POMPA WARMAN | 12X10 FA | |

| POMPA WARMAN | 12X10 FA | |

| POMPA WARMAN | 12X10GG | |

| POMPA WARMAN | ||

| POMPA WARMAN | 12X10 ST-G | |

| POMPA WARMAN | ||

| POMPA WARMAN | 14X12GG | |

| POMPA WARMAN | 14X12 GG-G | |

| POMPA WARMAN | 14X12TG | |

| POMPA WARMAN | 16X14GG | |

| POMPA WARMAN | 18X16GG | |

| POMPA WARMAN | ||

| POMPA WARMAN | 18X16 TG | |

| POMPA WARMAN |

Parte bagnata della pompa in ferro bianco ad alto contenuto di cromo

| OEM WEIR | DIMENSIONE DELLA POMPA | TIPO DI TELAIO | OPZIONI | PORTA | FODERA POSTERIORE | CIOTOLA | GIRANTE | |

|---|---|---|---|---|---|---|---|---|

| POMPA WARMAN | 6/4 | D/GG | G | METALLO | DG4131 | DG4137A05 | ||

| POMPA WARMAN | 6/6 | E/E | G | GOMMA | EG6013A05 | E4041MA05 | EG6131A05 | EG86137A05 |

| POMPA WARMAN | 8/6 | F F F | G | METALLO | EG86013A05 | E4041MA05 | EG6131A05 | EG86137A05 |

| POMPA WARMAN | 8/8 | F F F | G | GOMMA | FG8013A05 | FG8041MA05 | FG8131A05 | FG8137A05 |

| POMPA WARMAN | 10/8 | F/FF/S | G | METALLO | FG8041MA05 | FG8131A05 | FG8137A05 | |

| POMPA WARMAN | 10/8 | S | GH | GOMMA | FGH8013MA05 | FGH8041A05 | FGH8131A05 | FGH8137A05 |

| POMPA WARMAN | 12/10 | FA/FA/SOL/ST/TI | G | METALLO | GG10013A05 | FG10131A05 | FG10137A05 | |

| POMPA WARMAN | 12/10 | G/T | GH | GOMMA | GGH10013A05 | GGH10041A05 | GGH10131A05 | |

| POMPA WARMAN | 14/12 | G/GG/T | G | METALLO | GG1412013-1A05 | GG12041A05 | GG12131A05 | GG12137A05 |

| POMPA WARMAN | 16/14 | G/T | GH | METALLO | HG14041MA05 | HG14131A05 |

Per quanto riguarda il problema della tecnica della pompa dei liquami, la selezione, la richiesta, non esitate a contattarci.