AlphaFlo®

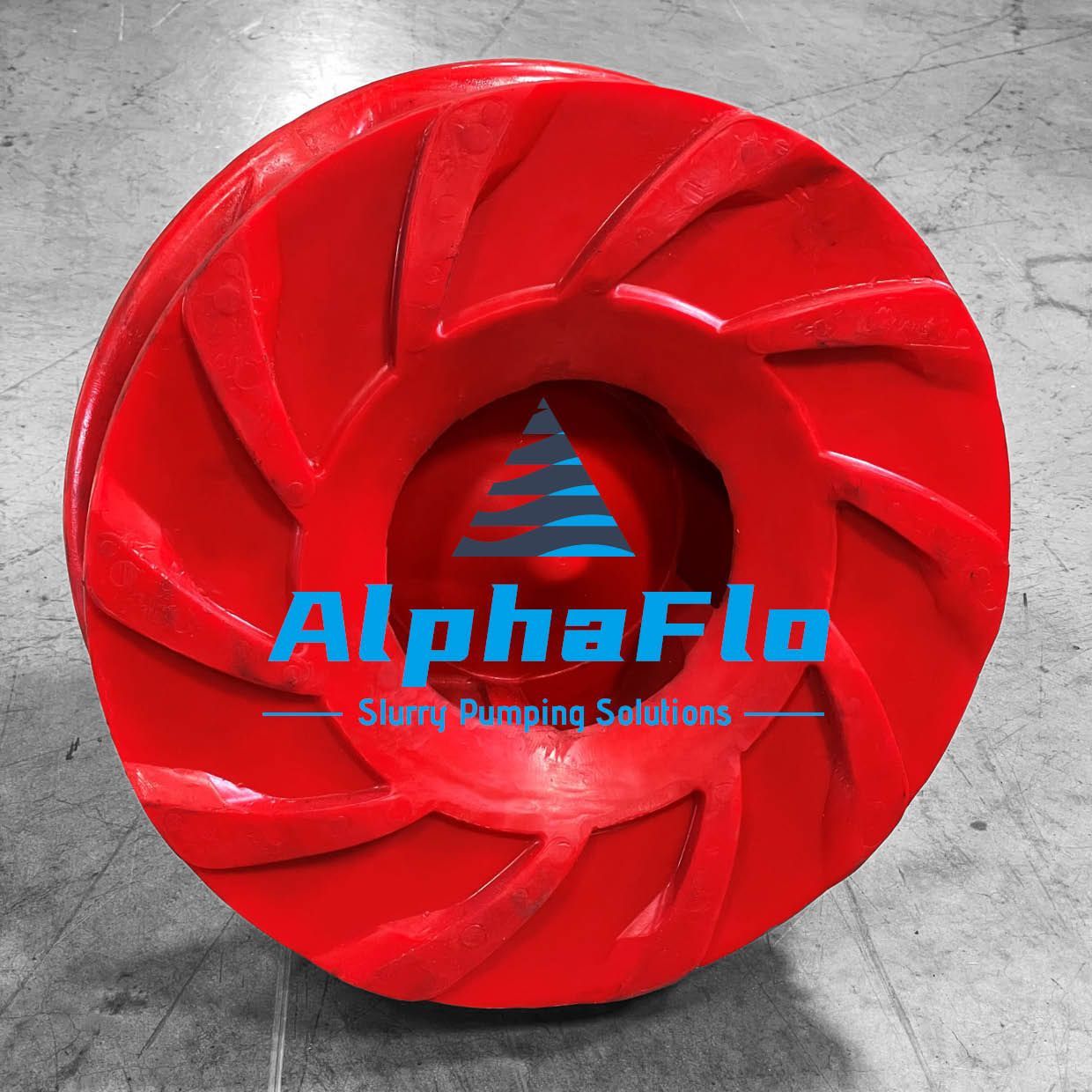

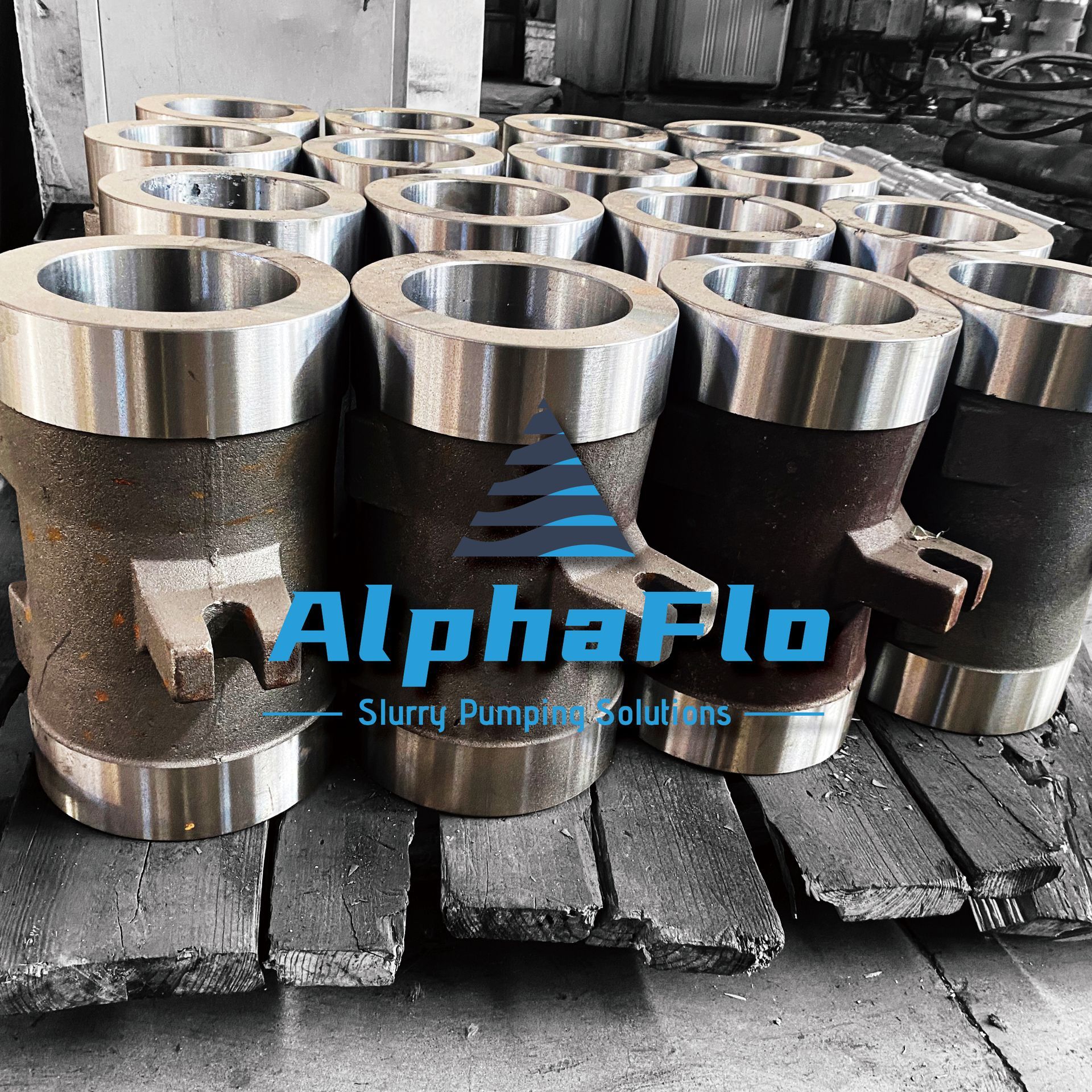

Slurry Pump Parts

High-quality heavy-duty centrifugal slurry pump spare parts from AlphaFlo®

The foundamental of pumping solids slurry means that destructive wear on internal parts is an inevitable part of the life cycle of your slurry pumps.

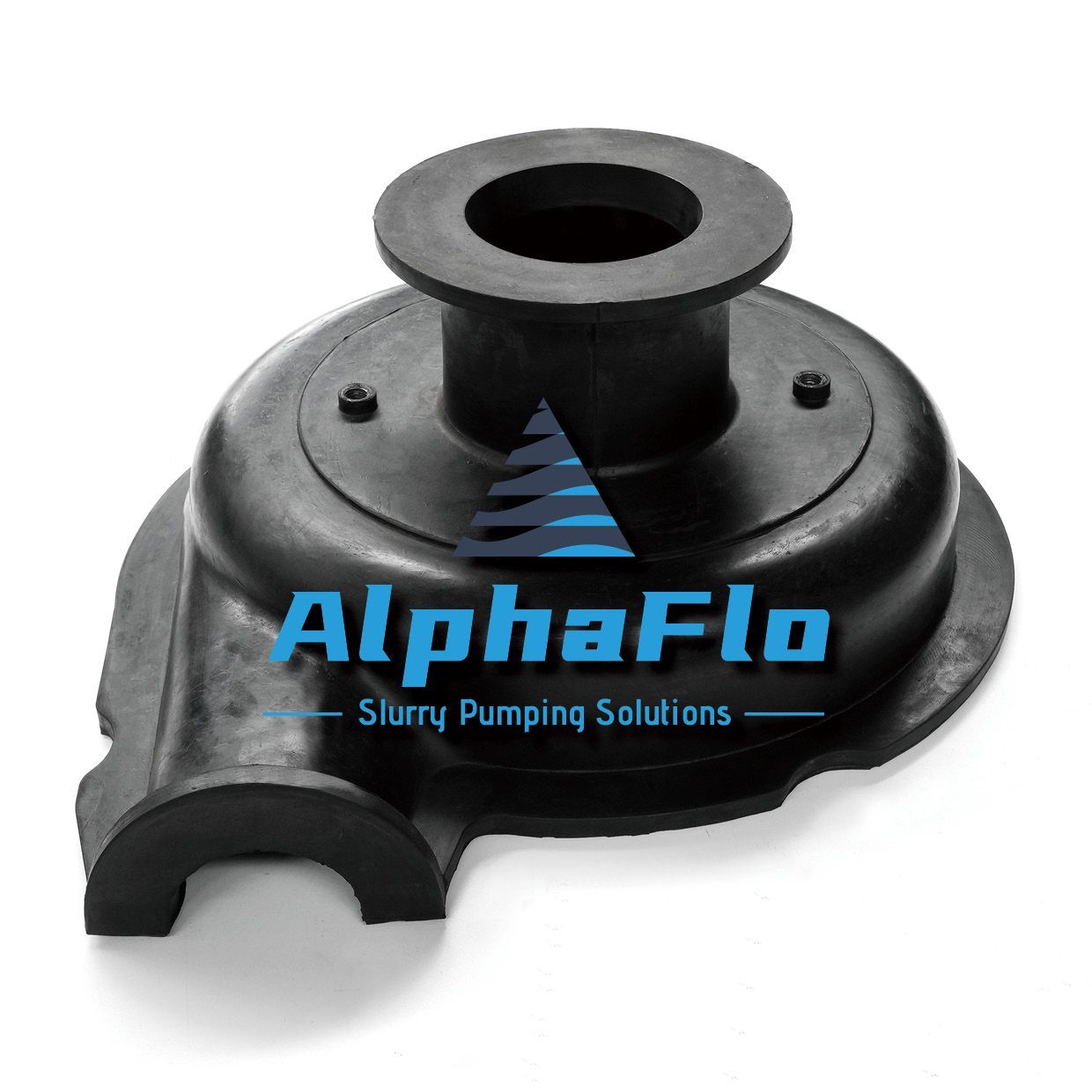

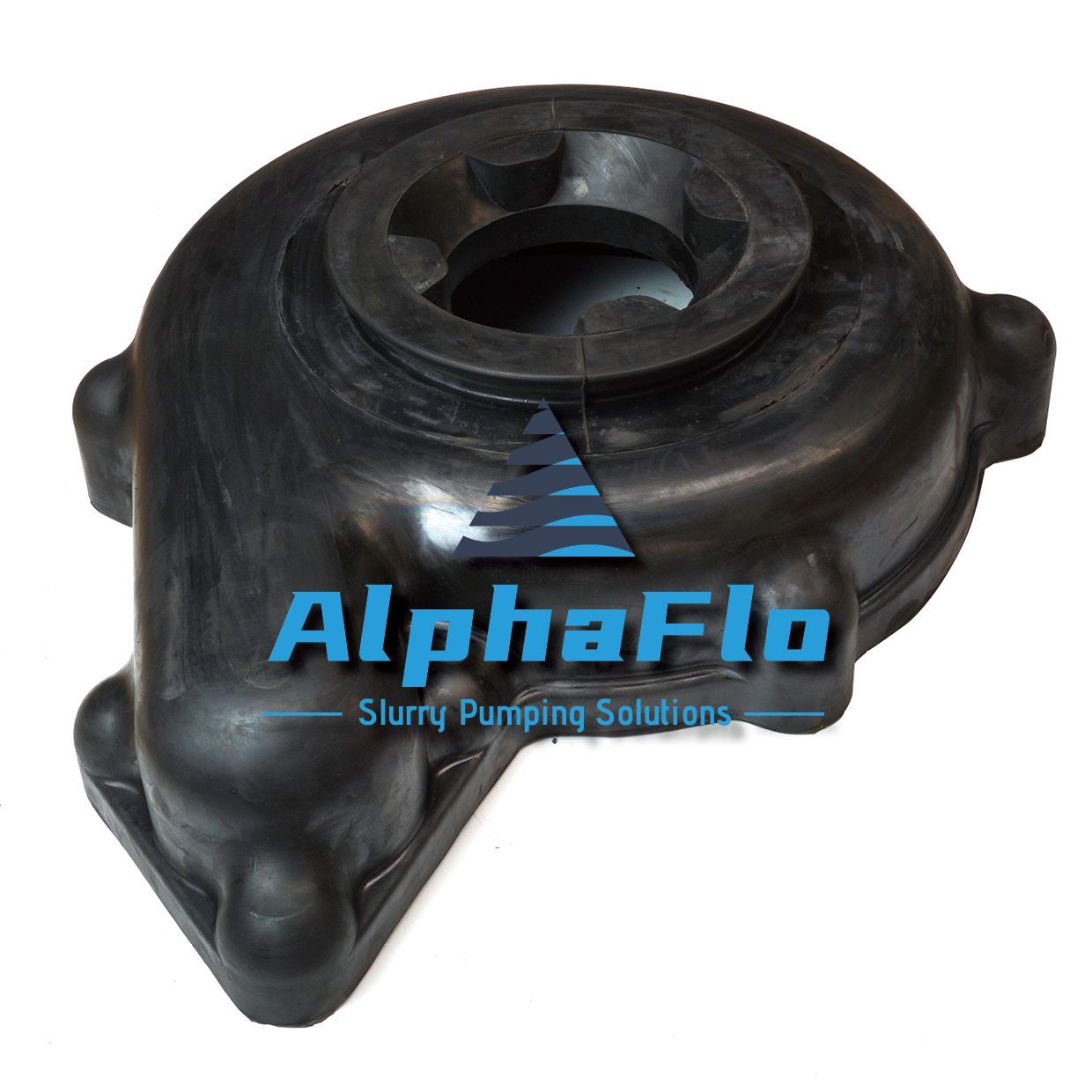

AlphaFlo® manufactures top quality metal and elastomer replacement parts fully compatible with Warman pumps, and provides value to customers through fair pricing and lead times that are some of the lowest in the market. We stock bulk slurry parts, all of which are interchangeable with Warman slurry pump parts. We maintain a global distribution network that stands ready to serve your process needs.

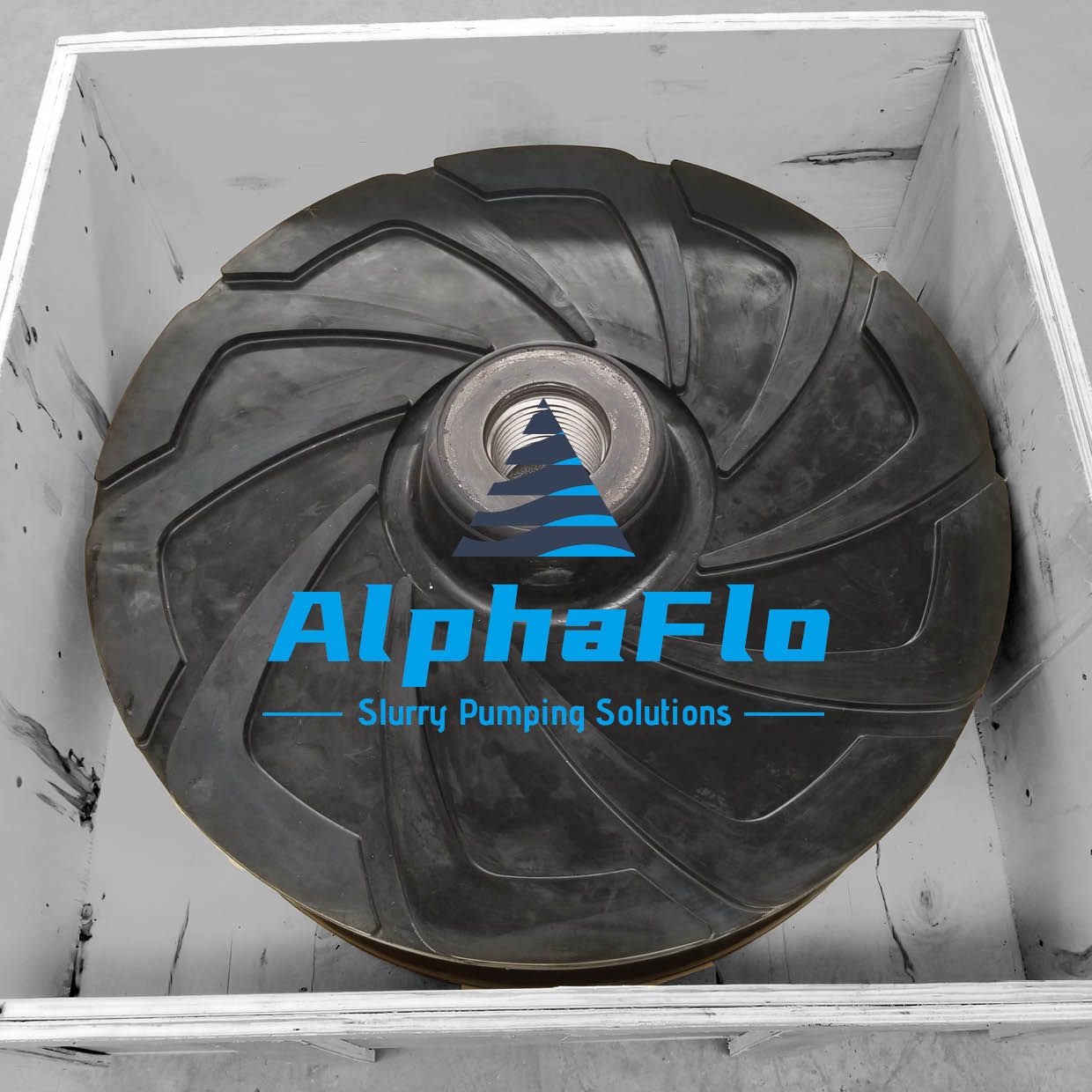

All parts compatible with the Warman slurry pumps have been rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance. AlphaFlo® manufactures replacement parts for other manufacturers as we do our own: with technical expertise, quality, fair pricing, and product availability for the end users.

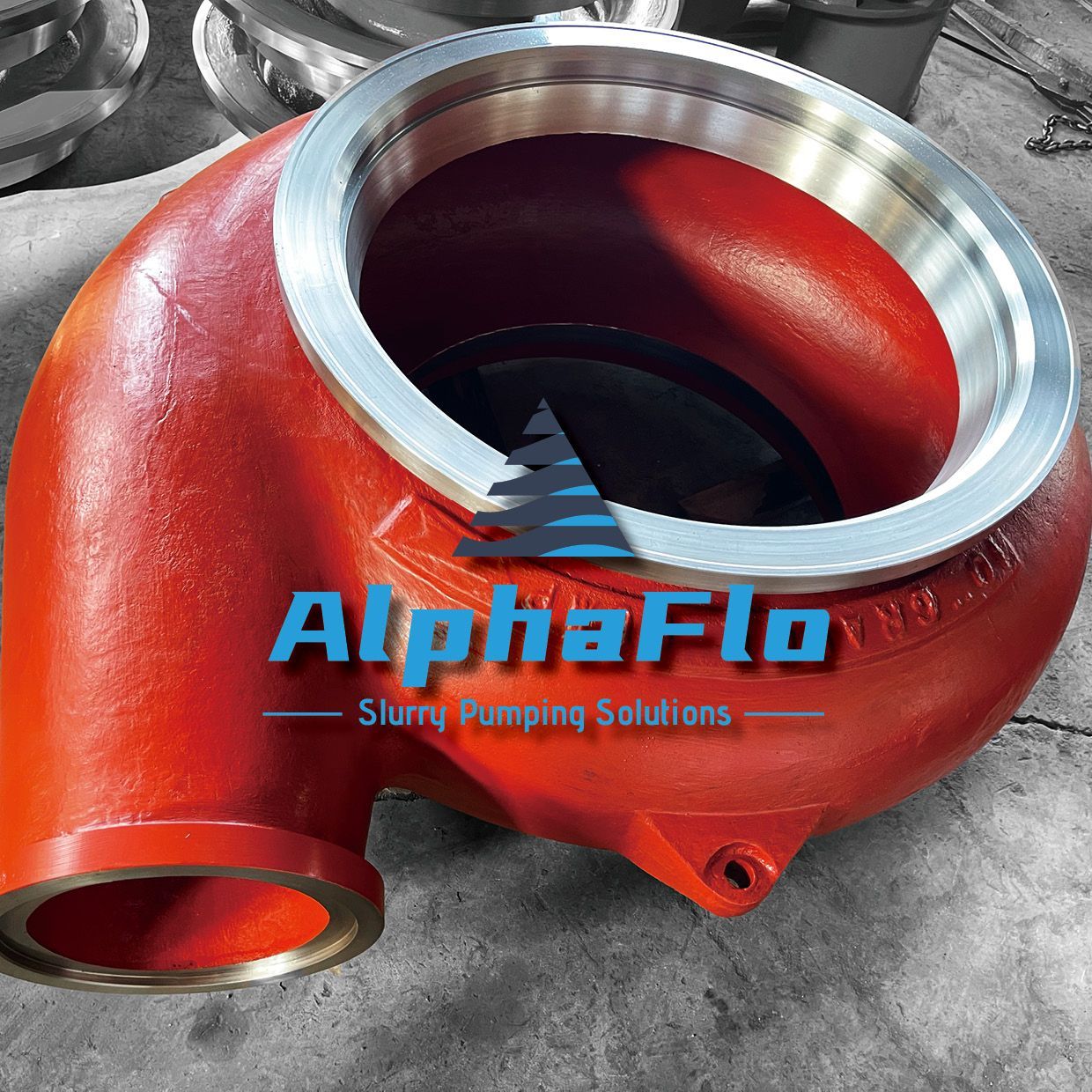

Hard metal wet end

AlphaFlo high chrome slurry pump parts manufactured to the highest degree of mechanical integrity through the use of accurate 3D modeling.

Reversing Engineering

We use the latest SolidWorks and FaroArm technology to design precise parts at the beginning our manufacturing process, and inspect and verify those parts before shipping.

Materials

Rubber&Elastomer

Look for reliable OEM aftermarket slurry pump parts, please don't hesitate to inquiry AlphaFlo.