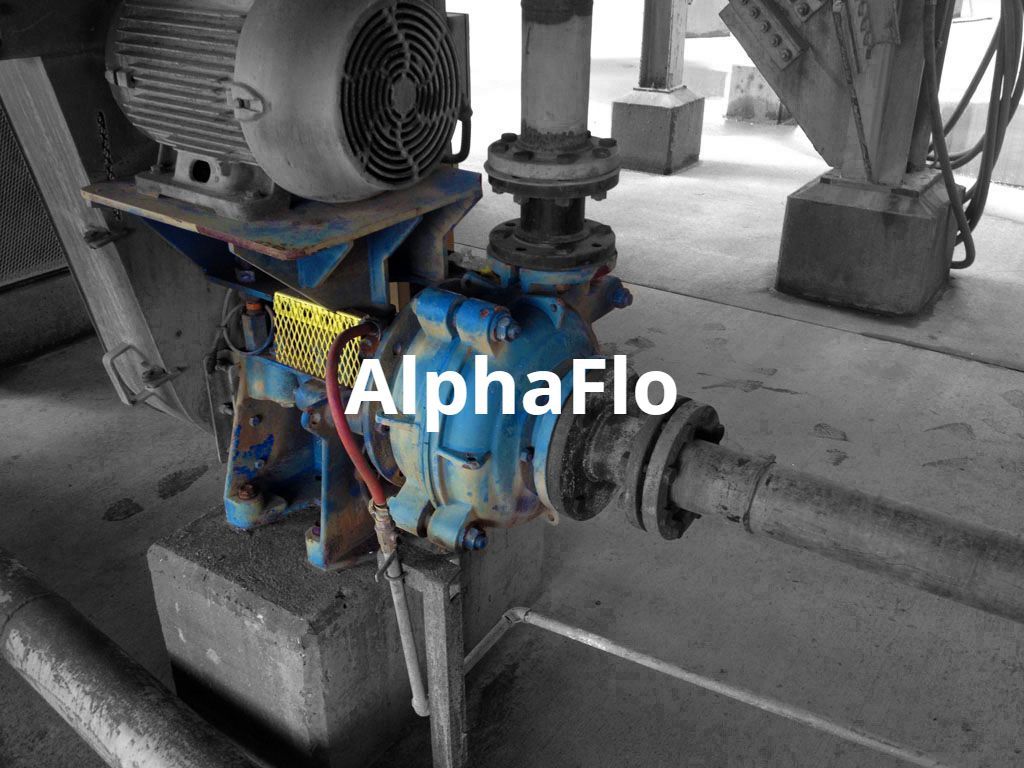

AlphaFlo®

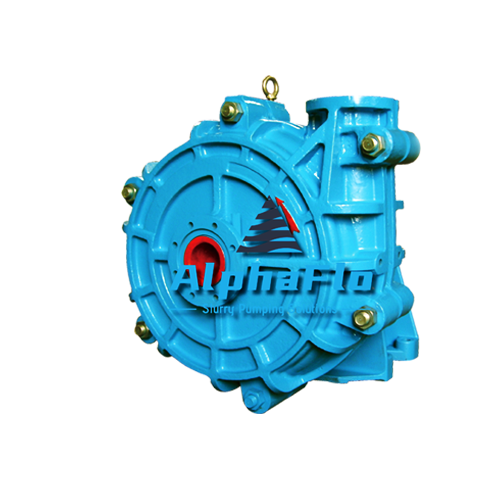

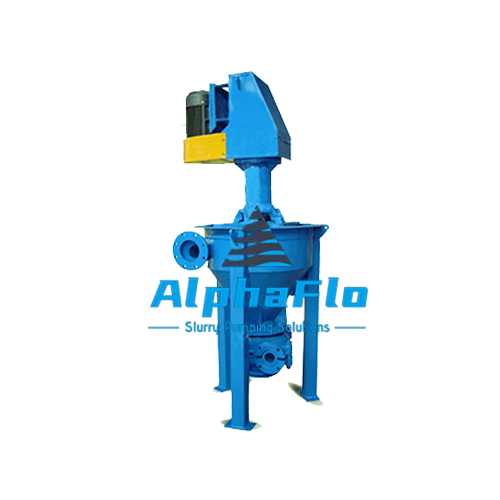

Slurry Pumps

You can turst our expertise,technology and support service to meeting your

slurry transport requirement as always.

AlphaFlo® supplies a complete range of slurry pumps for medium and heavy duty slurry applications, including cyclone feed, spirals feed, mill discharge, tailings disposal, filter feed, effluent discharge.

Available with short lead times, our pumps are designed to efficiently transfer abrasive and corrosive slurries in wide range of industries, from mining and mineral processing to pulp and paper and wastewater treatment.

Our robust and durable slurry pump design incorporate specialised casings and wear-lining technologies to maximise uptime.

- Ideal for highly abrasive & corrosive slurries

- Constructed with various alloys (high chrome iron) & rubbers to reduce wear & minimise downtime

- Replaceable impeller & liners improve protection & simplify maintenance

| AlphaFlo® | A | H | L | G | V | F(H) | F(V) | D | AJ | AG |

|---|---|---|---|---|---|---|---|---|---|---|

| OEM | AH | HH | L | G | SP | AHF | AF | GSL | ZJ | ZGB |

| Parameters | ||||||||||

| Size | 1~18" | 1~6" | 20~650mm | 4~16" | 65~250mm | 2~18" | 2~8" | 600~1000mm | 40~300mm | 65~300mm |

| Flow m3/h | 5400 | 1152 | 10260 | 3300 | 1089 | 5000 | 575 | 15500 | 2333 | 1920 |

| Head m | 68 | 98 | 57 | 78 | 38 | 65 | 30 | 42 | 133 | 94 |

| Wet End Mat. | M/R | M | M/R | M | M/R | M/R | M/R | M/R | M | M |

| Structure | H | H | H | H | V | H | V | H | H | H |

| Applications | ||||||||||

| Mill Discharge | * | * | ||||||||

| Coarse Sand | * | * | * | * | * | |||||

| Coarse Tailings | * | * | * | * | * | |||||

| Phosphate Matrix | * | * | * | * | * | * | * | |||

| Fine Tailings | * | * | * | * | * | * | * | |||

| Heavy Media | * | * | * | * | * | * | ||||

| Dredging | * | |||||||||

| Gypsum | * | * | * | * | * | * | * | * | ||

| Coal Washing | * | * | * | * | * | * | * | |||

| FGD | * | * | * | * | * | * | * |

Remarks:

Size. Pump discharge size in mm or inch

Wet End Material. M means hard metal and R means elastomer

Structure. H means horizontal and V is vertical

OEM. Weir Warman Pump.

AlphaFlo's slurry pump & parts interchangeable with OEM but not affilicated with OEM.