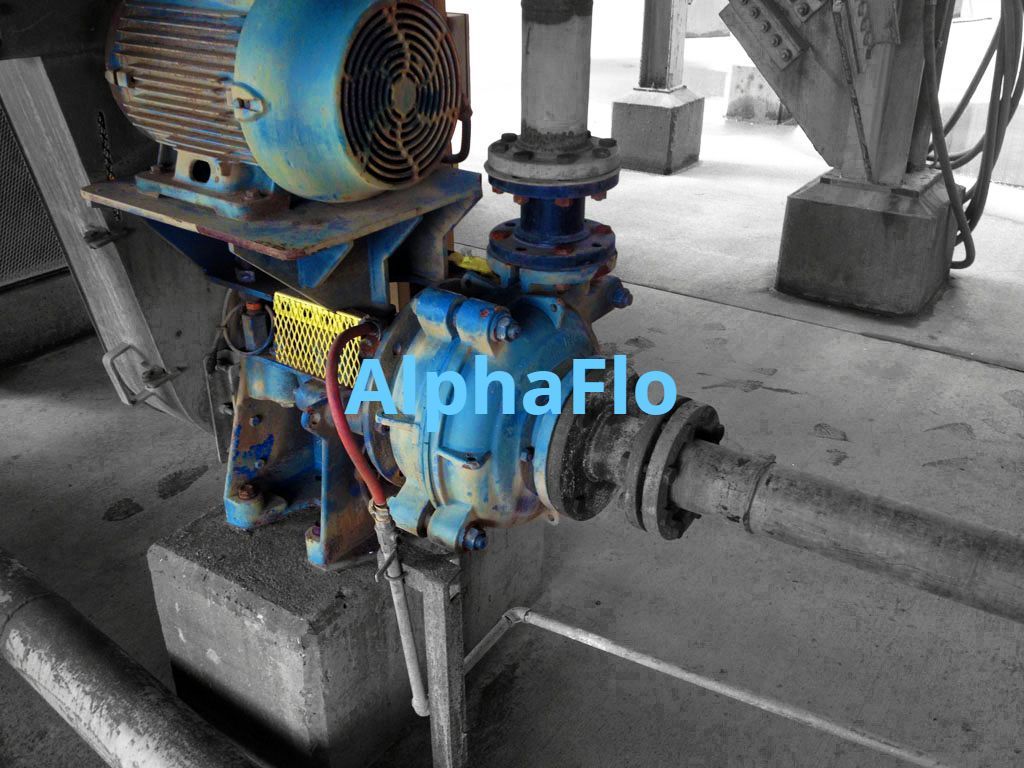

AlphaFlo®

Heavy Duty Slurry Pumps

You can turst our expertise,technology and support service to meeting your

slurry transport requirement as always.

AlphaFlo® A series extra heavy duty horizontal centrifugal slurry pumps for continuous pumping of highly abrasive or dense slurries in processes from cyclone feed to regrind, flotation and tailings.

(Interchangeable with OEM

Warman AH Pump)

Features:

- Casing. two halves radially split casing with minimum casing bolts reducing maintenance and minimise downtime.

- Impeller & liner. hard metal of versatile 27~30% chrome white iron and natrual rubber & synthetic elastomers moulded impeller and liner available in various abrasion & corrosion resistance slurry pumping applications.

- Bearing Assembly. removeable cartridge style grease luburicated bearing assembly can be replaced with the base.Also oil lubricated heavy duty bearing assemblies available.

- Shaft sealing. centrifugal seal (dry-seal,elimination gland seal water),common gland seal and mechanical seal.

- Metal and rubber lined pump. they share the same footprint,same bearing assembly,base,shaft sealing parts (stuffing box ,expeller,expeller ring,shaft sleeve,lantern restrictor/ring,gland,packing).

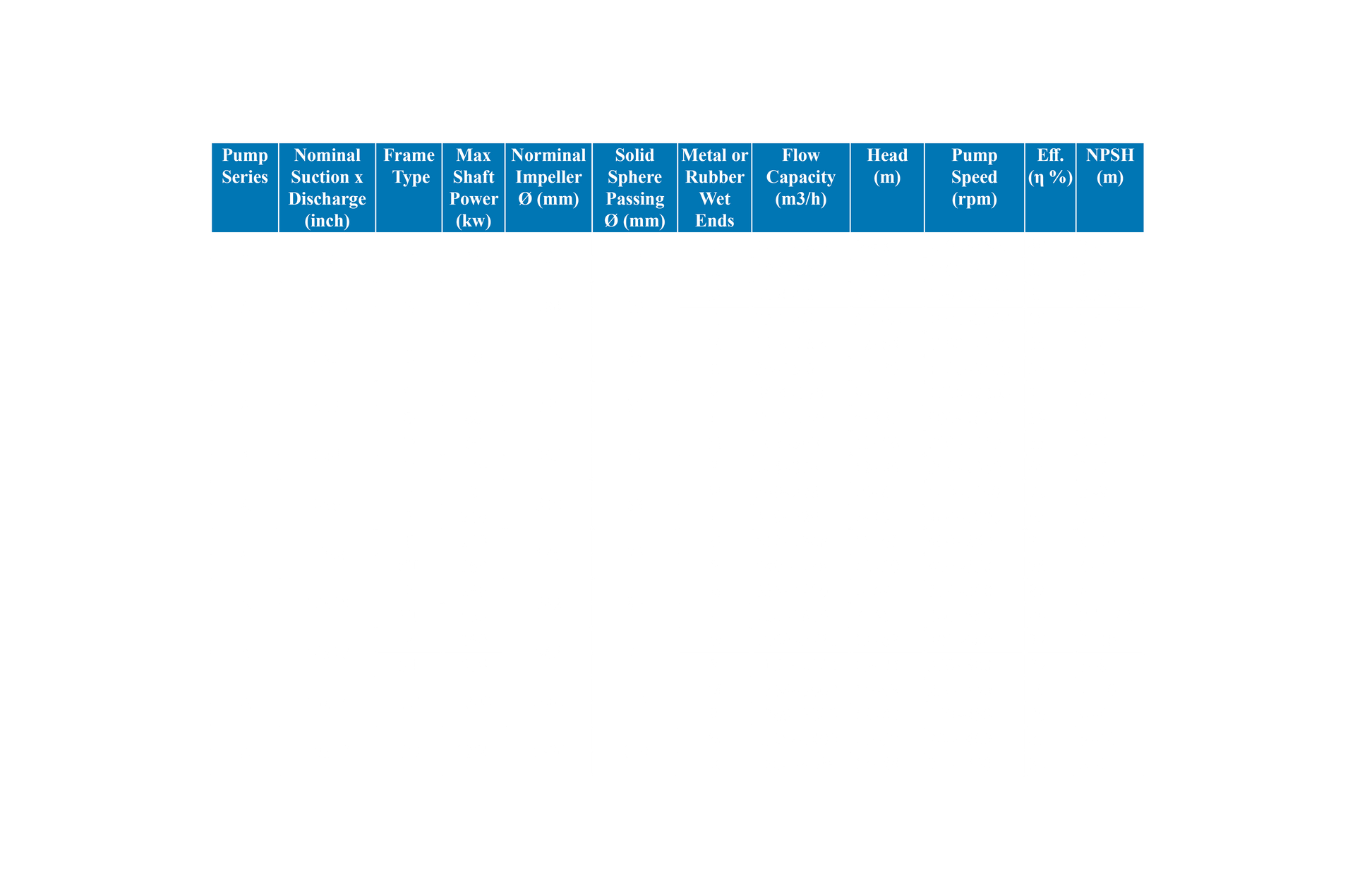

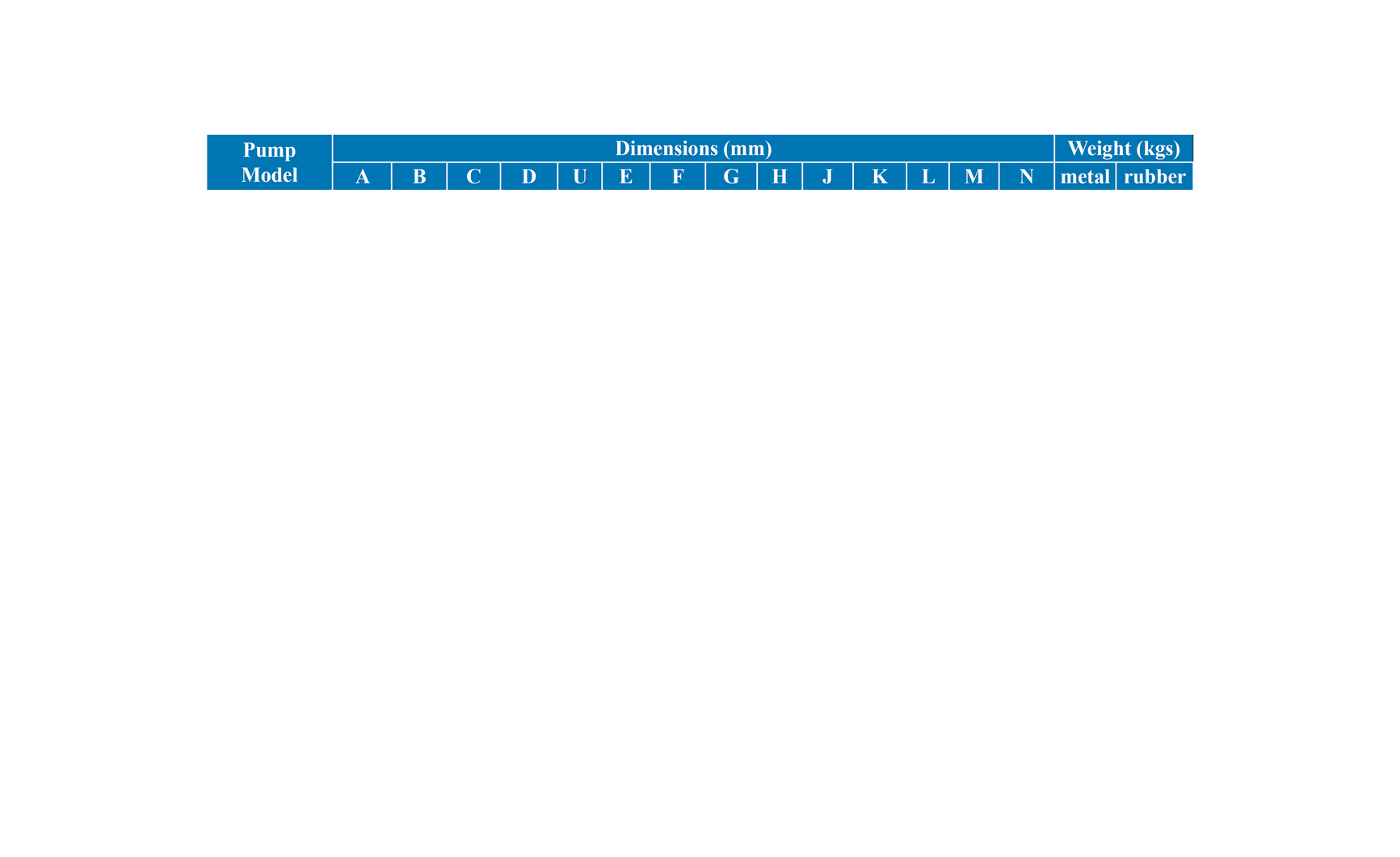

Specifications:

- Size range (discharge) 25 mm to 450 mm (1” to 18”)

- Capacities to 5 000 m3/hr (22 000 gpm)

- Heads to 73 m (240 ft)

- Pressure to 2 020 kPa (300 psi)

Typical applications:

- Heavy minerals

- Mill discharge

- Cyclone feed

- Paper and pulp

- Sugar beet

- Fly ash

- Slag Granulation

Mineral Processing

- Coal Washing

- Phosphoric Acid Slurry

- Sand Seperation

Industrial Processing

- Sugar Industry

- Chemical Process

- Pulp Paper

- Fuel Gas Desulfurization

About slurry pump technique issue,slection,inquiry,please don't hesitate to contact us.