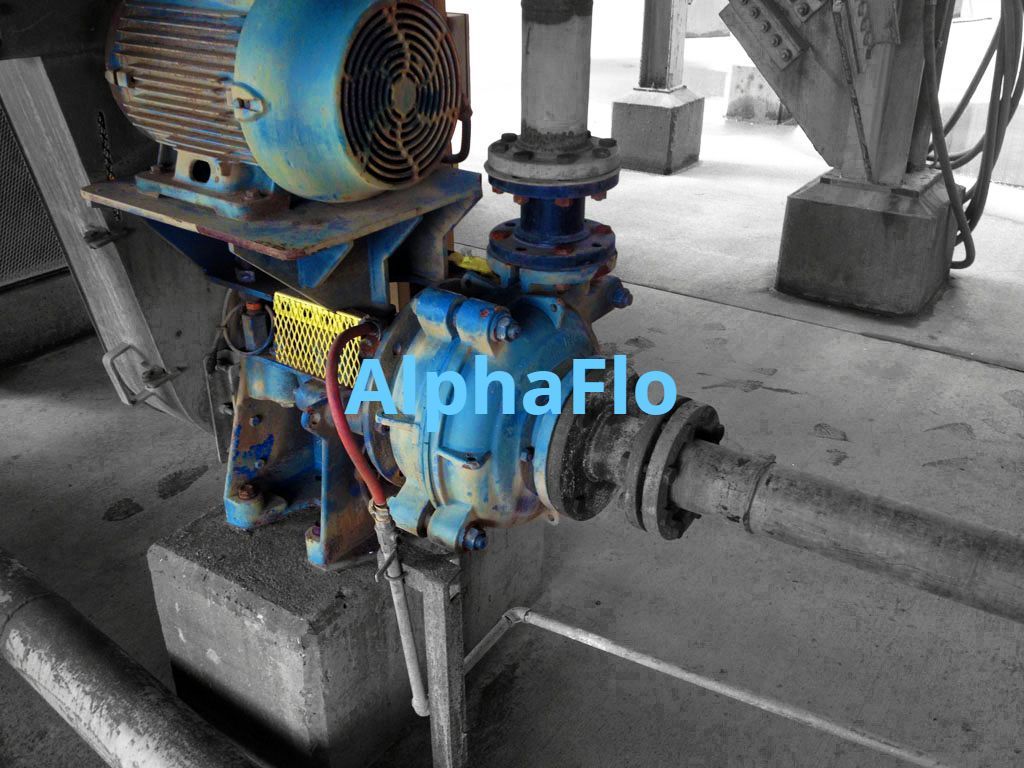

AlphaFlo®

Gravel Pumps

You can turst our expertise,technology and support service to meeting your

slurry transport requirement as always.

AlphaFlo® G series gravel pumps

are designed for gravel and dredging operations to handle very large particles specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Its capability of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities, further increasing component life.

(Interchangeable with OEM Warman G&GH Seires Gravel Pump)

Features:

- Casing. The large, robust casing has been designed to reduce internal velocities, resulting in minimum efficiency loss and improved casing wear life. The casing is made up of three components to reduce maintenance time and costs associated with a one-piece design.

- Impeller. Front and back shroud expulsion vanes reduce gland pressure and intrusion of high concentrations of solids in the gland area. Efficiency is maintained by minimizing suction side recirculation. Specially designed and shaped impeller vanes allow the handling of extraordinarily large particles.

- Bearing Assembly. removeable cartridge style grease luburicated bearing assembly can be replaced with the base.Also oil lubricated heavy duty bearing assemblies available.

- Shaft Seal. centrifugal seal (dry-seal,elimination gland seal water),common gland seal and mechanical seal.

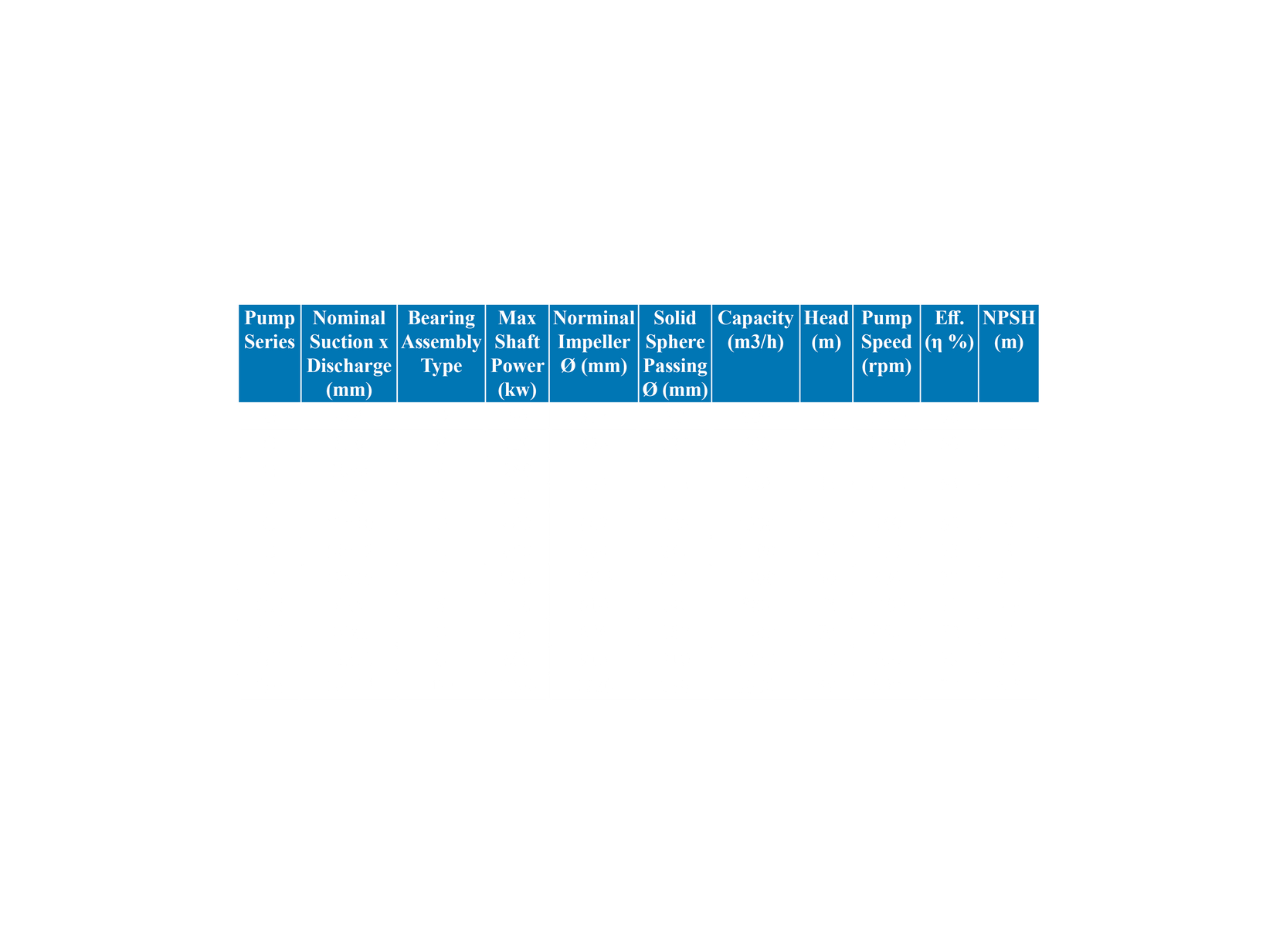

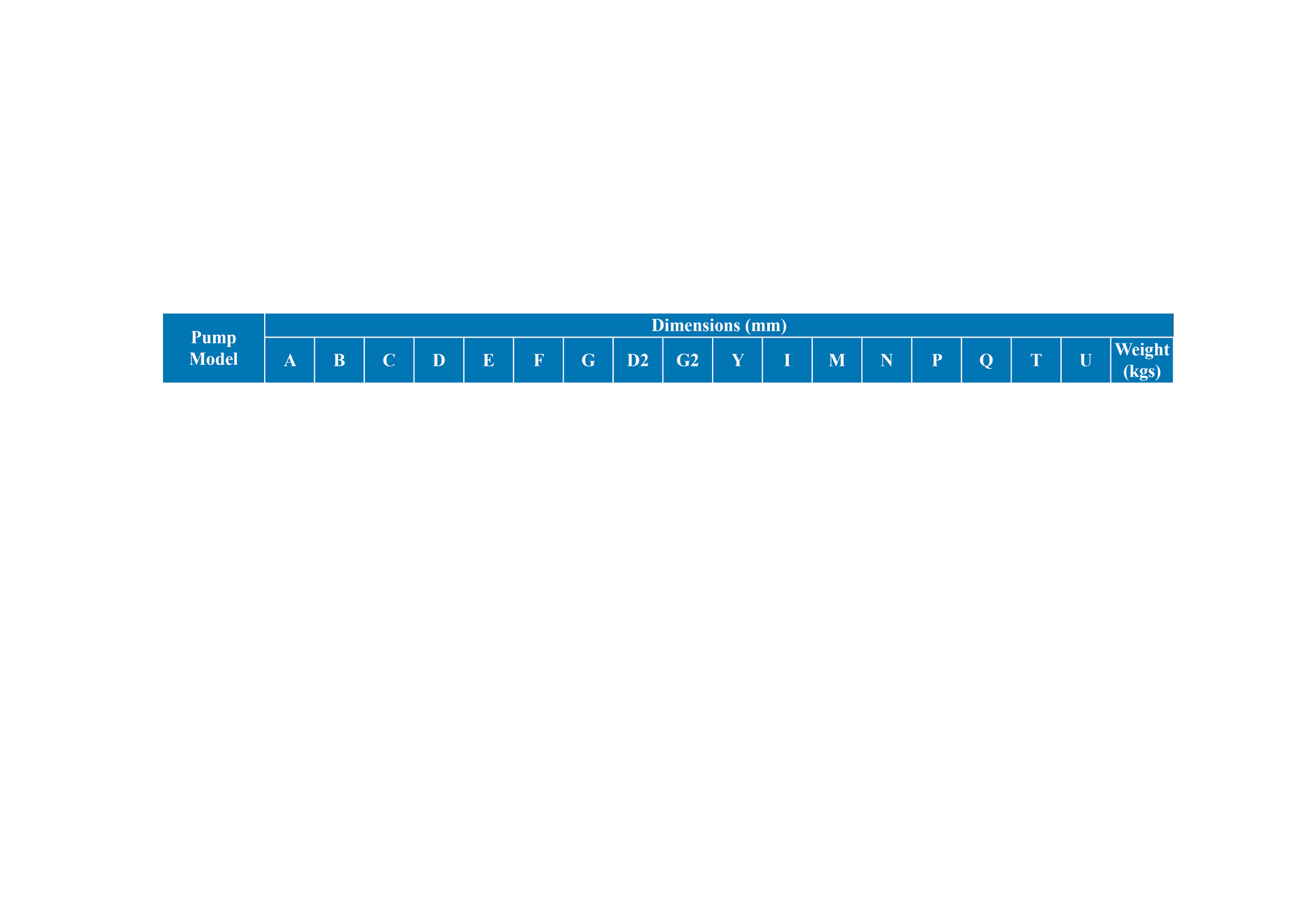

Specifications:

- Discharge diameters : 4” to 14” (100 mm to 350 mm)

- Heads through 225 ft (70 m)

- Flow rates through 12,000 gpm (2,700 m3/h)

- Casing pressure tolerance 200 psig (1,380 kPa)

Typical applications:

- Cyclone Feed

- Dredging

- Suction Hopper

- Tunnelling

- Mill Discharge

Hard Rock Mining

- Mine Dewatering

- Mill Discharge

- Concentrator

- Agglomerators

- Tailings

Mineral Processing

- Coal Washing

- Phosphoric Acid Slurry

- Sand Seperation

Industrial Processing

- Sugar Industry

- Chemical Process

- Pulp Paper

- Fuel Gas Desulfurization

About slurry pump technique issue,slection,inquiry,please don't hesitate to contact us.