AlphaFlo®

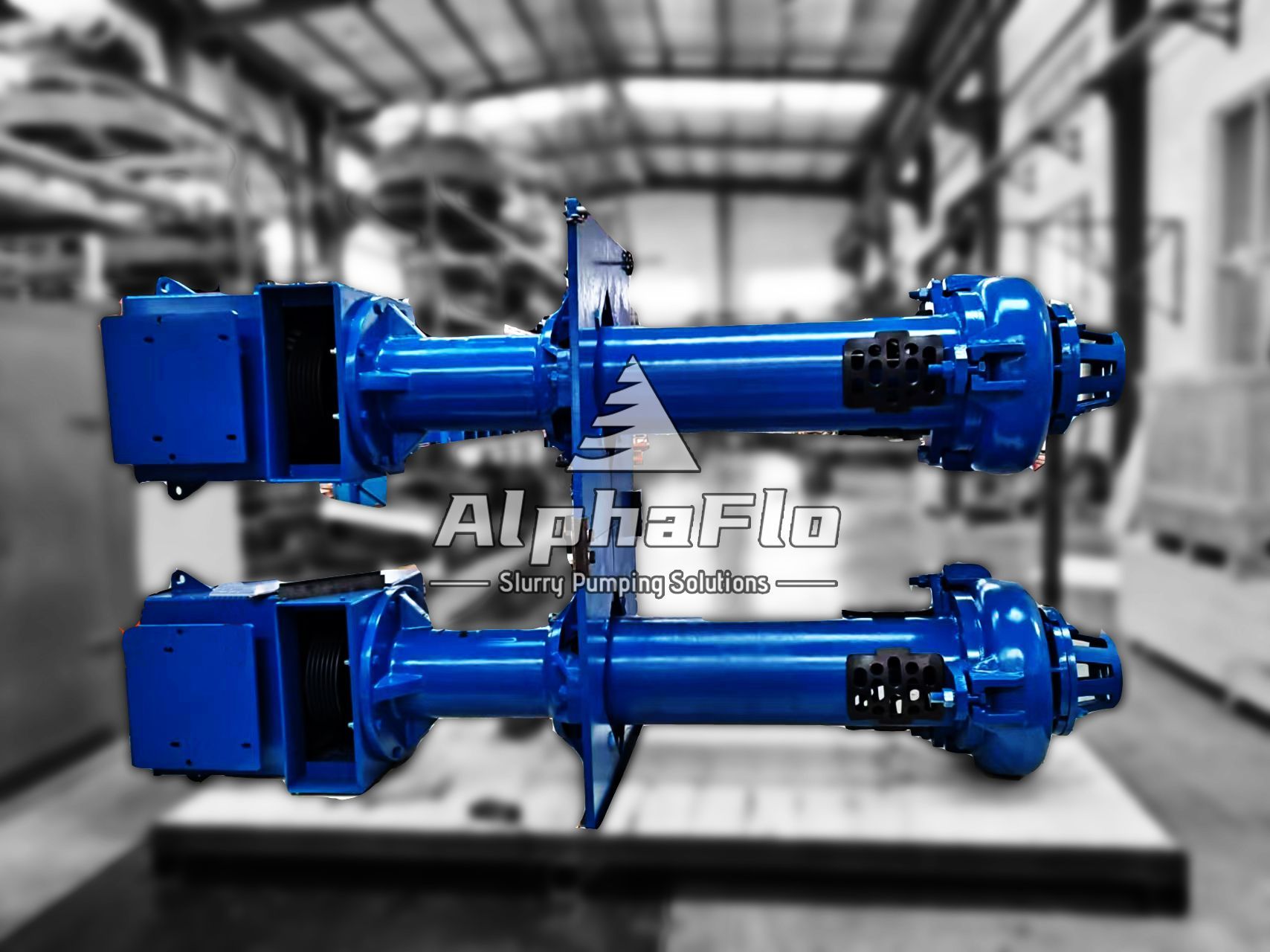

Vertical Slurry Pumps

You can turst our expertise,technology and support service to meeting your

solid slurry pumping requirement as always.

AlphaFlo® V range vertical slurry pumps are ideal for a variety of submerged suction pumping applications.

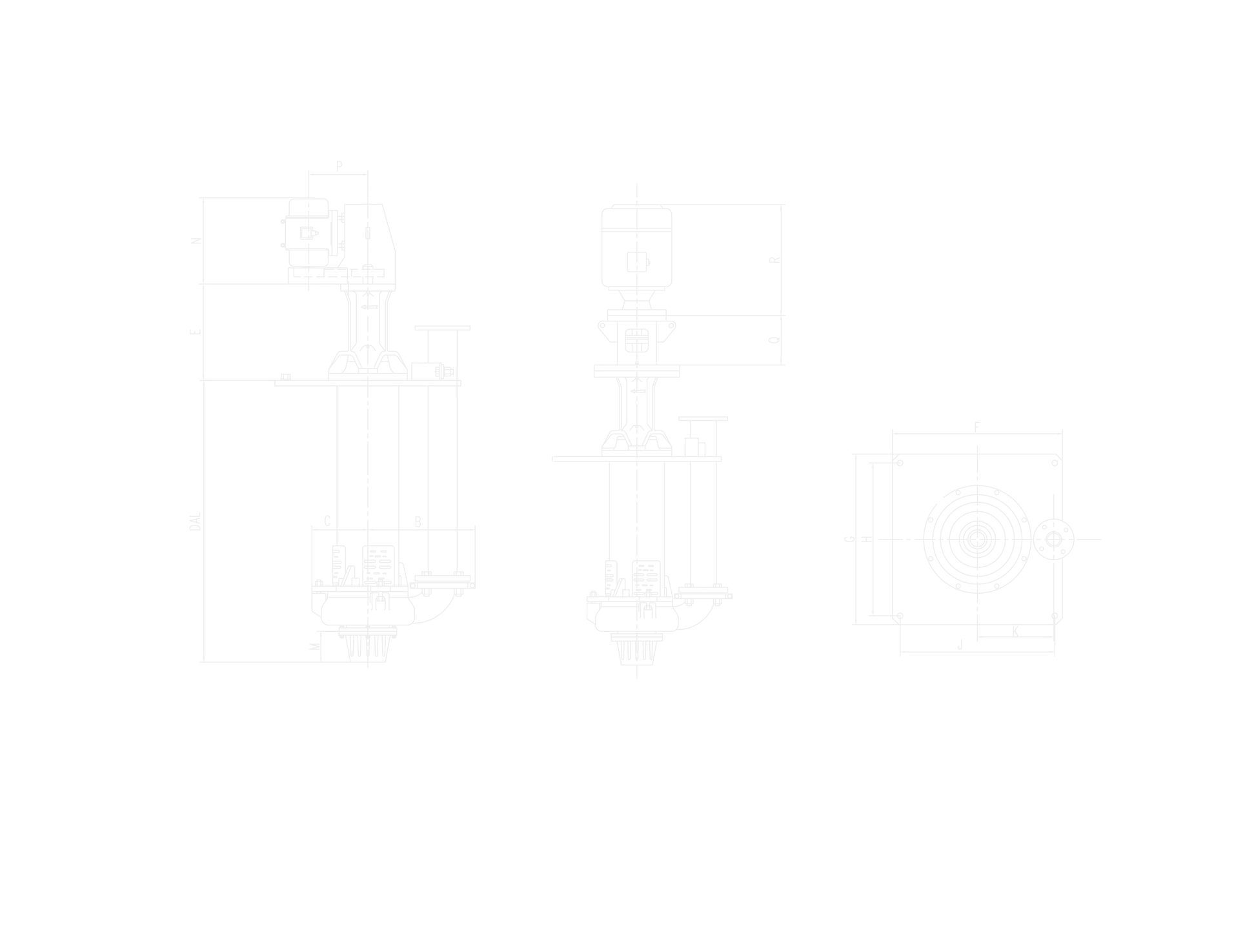

They operate well in a variety of sump conditions, and can also be readily applied on floating dewatering or other floating pump platforms. As a cantilevered vertical slurry pump, the V series does not have submerged bearings or seals, thus eliminating the primary failure mechanism for similarly fielded pump lines.

(Interchangeable with OEM WARMAN SP&SPR Seires Slurry Pump)

Features:

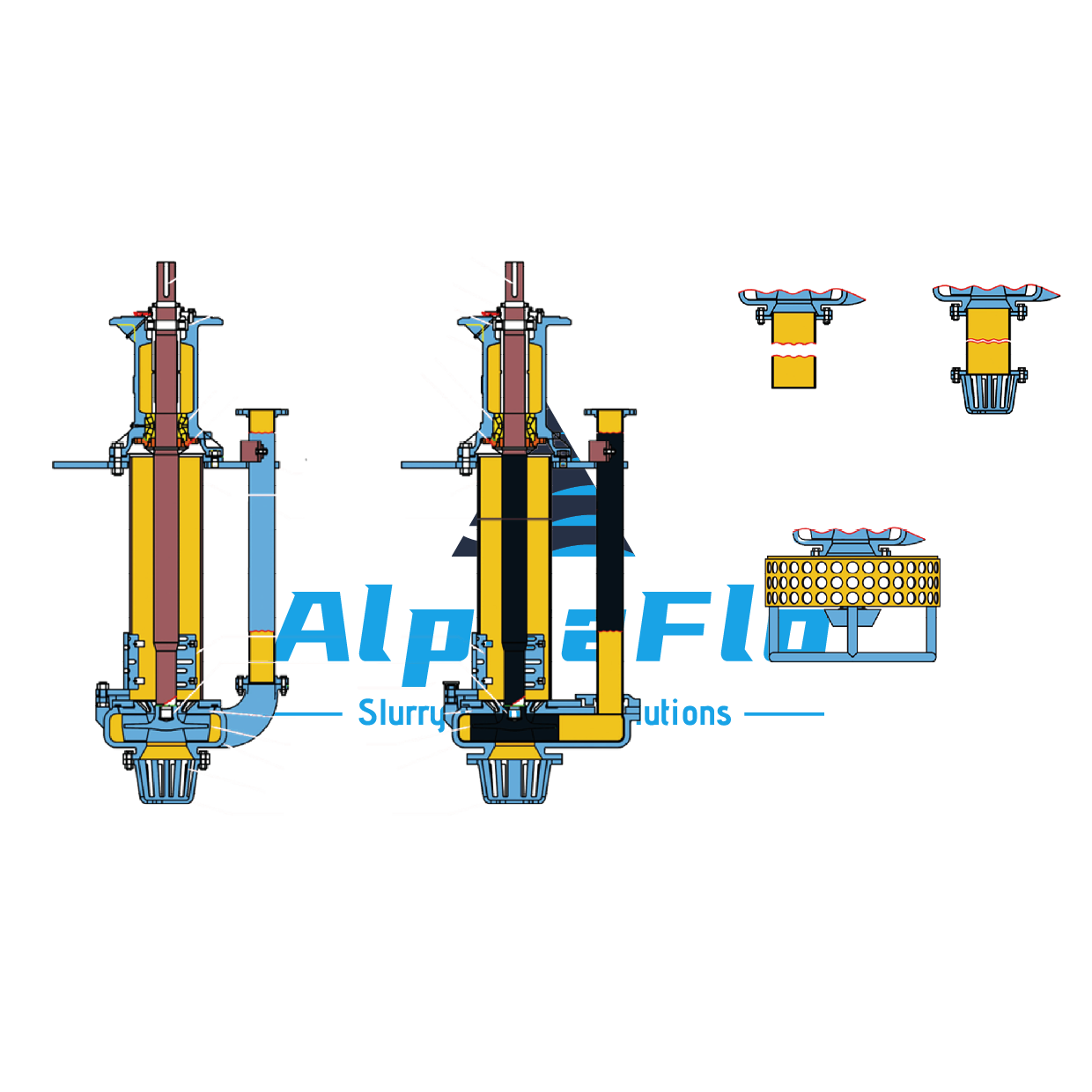

- Casing. Metal pumps have a heavy-walled abrasive-resistant 27% chrome alloy casing and rubber pumps have a molded rubber casing adhered to sturdy metal structures.

- Impeller. Double suction impellers; fluid flow enters the top as well as the bottom. This design eliminates shaft seals and reduces thrust load on the bearings.

- Bearing Assembly. The maintenance friendly bearing assembly has heavy-duty roller bearings, robust housings, and a massive shaft.

- No Shaft sealing. Fully Cantilevered – Eliminates submerged bearings, packing, lip seals, and mechanical seals that other vertical slurry pumps typically require.

- Column and Discharge Pipep. Steel columns and discharge pipes for metal pump and rubber-covered columns and discharge pipes for rubber pump.

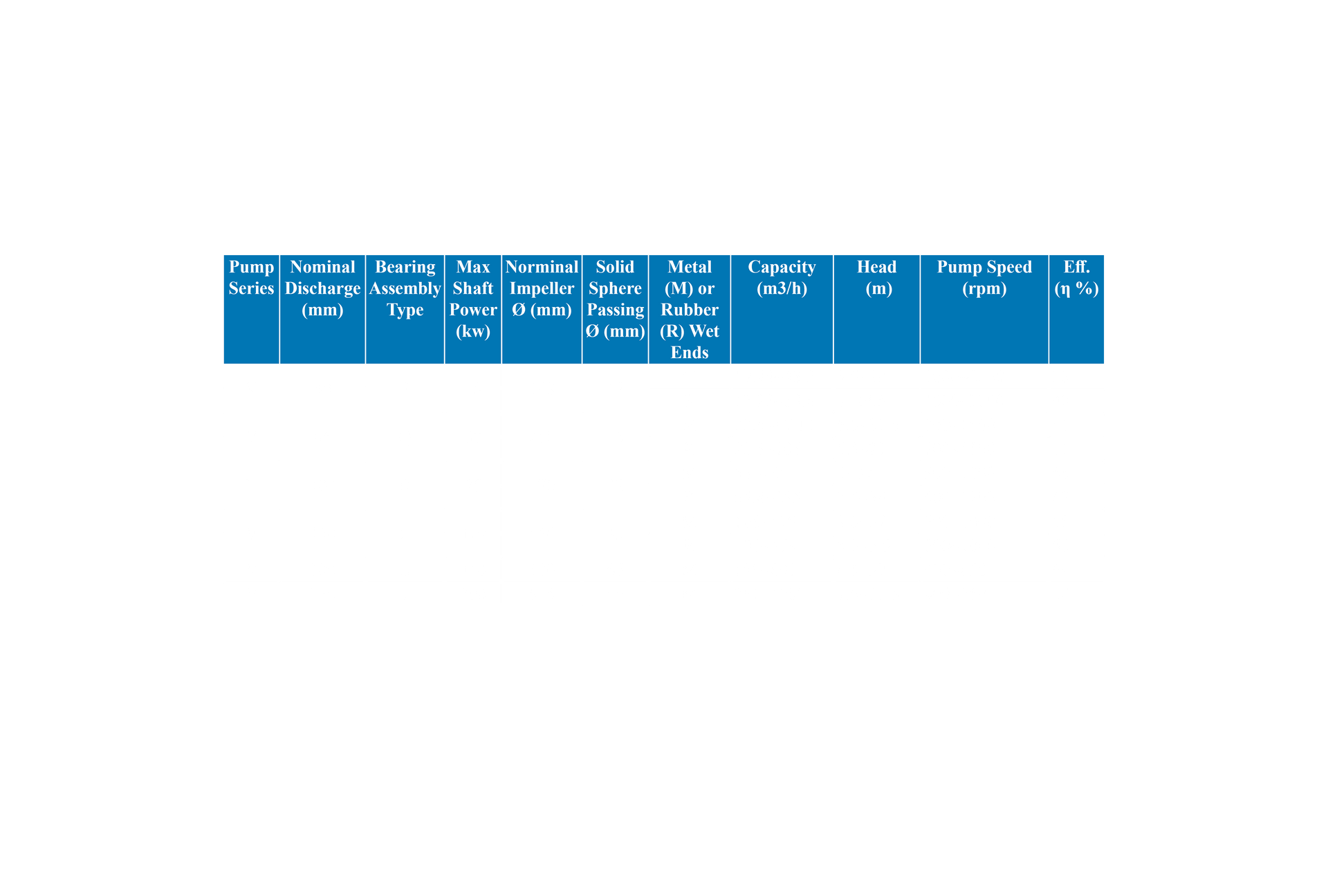

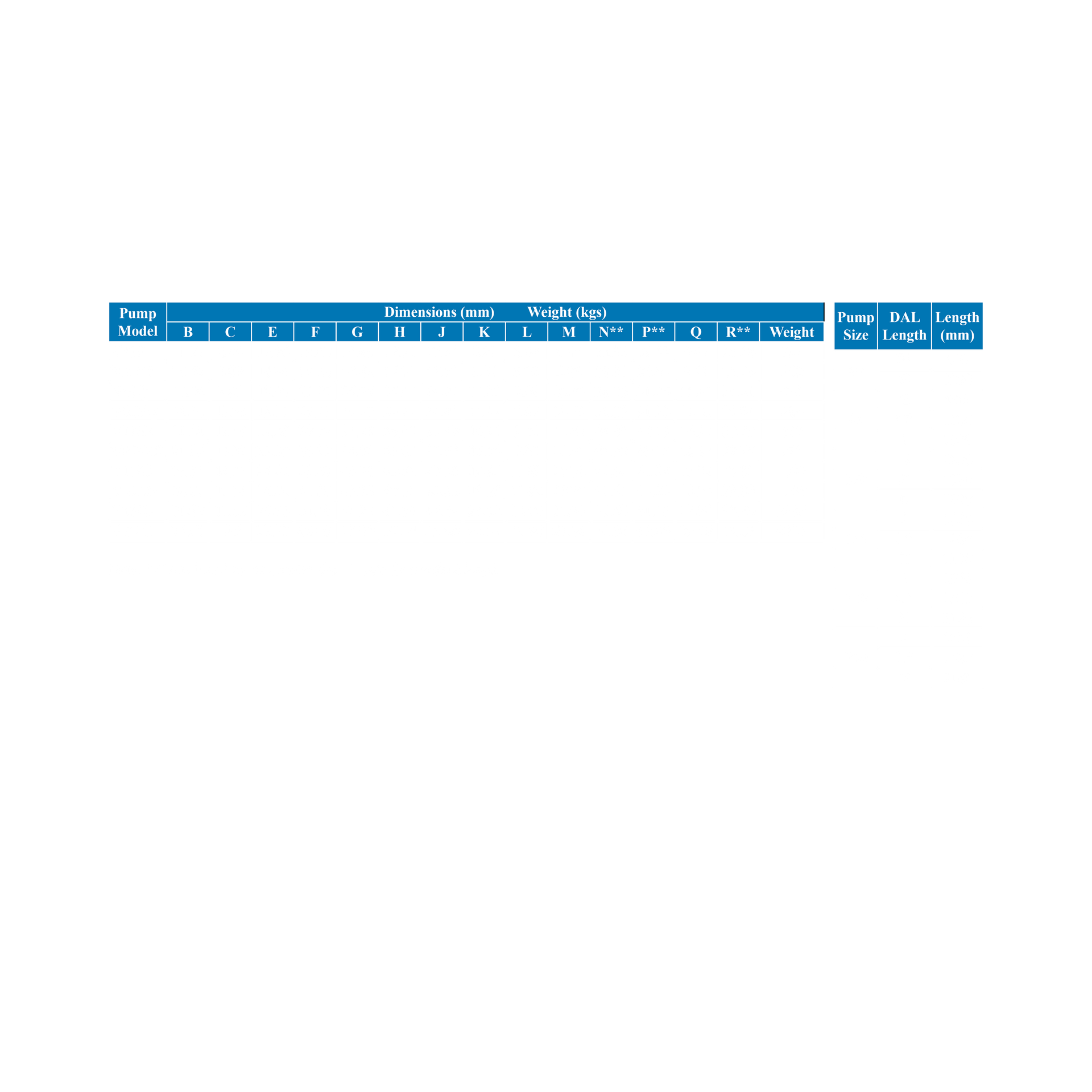

Specifications:

- Size range (discharge) 1.5″ to 10″ (40 mm to 250 mm)

- Capacities to 5 000 m3/hr (22 000 gpm)

- Heads to 160 ft (50 m)

- Pressure to 6,000 gpm (1,350 m3/h)

Typical applications:

- Minerals processing

- Coal preparation

- Chemical processing

- Effluent handling

- Sand and gravel

Hard Rock Mining

- Mine Dewatering

- Mill Discharge

- Concentrator

- Agglomerators

- Tailings

Mineral Processing

- Coal Washing

- Phosphoric Acid Slurry

- Sand Seperation

Industrial Processing

- Sugar Industry

- Chemical Process

- Pulp Paper

- Fuel Gas Desulfurization

About slurry pump technique issue,slection,inquiry,please don't hesitate to contact us.