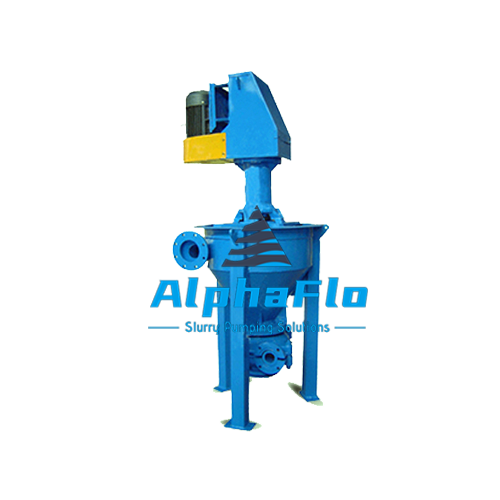

AlphaFlo®

Vertical Froth Pumps

You can turst our expertise,technology and support service to meeting your

slurry transport requirement as always.

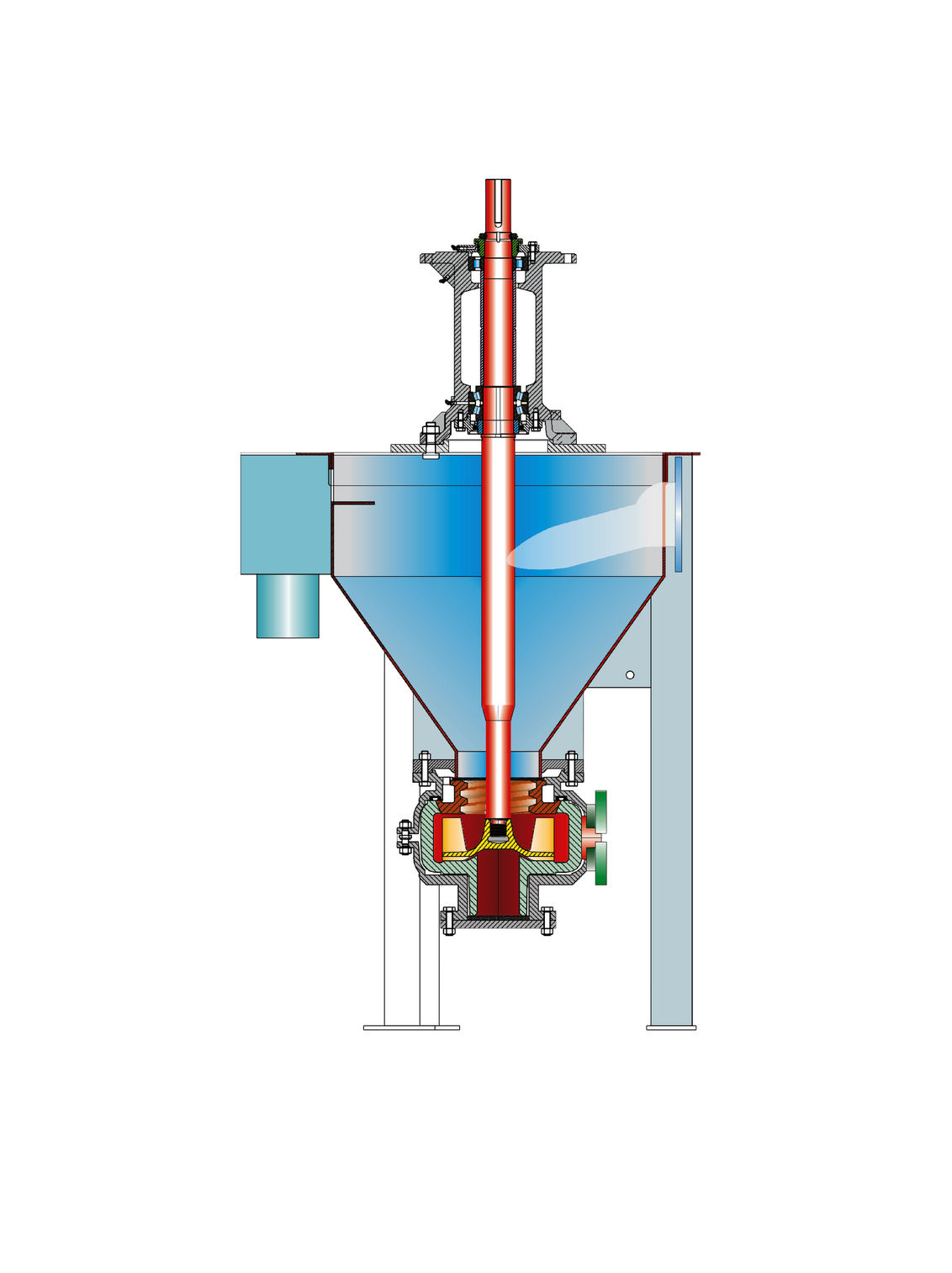

AlphaFlo® A series a vertical cantilever pump completely with hopper which utilises casing and liners from the AlphaFlo A series. Designed to pump mineral froth more efficiently by de-aerating or partially deaerating the froth before it enters the pump head,utilising and included vortext princiapal

(Interchangeable with OEM Warman AF Seires Slurry Pump)

Features:

- Impeller. Semi-open impeller designs with vanes located on both sides of the shroud are suitable for pumping froth.

- Metal and rubber lined pump. Totally interchangeable thick rubber or hardened metal liner.

- Casing. Two halves radially split casing with minimum casing bolts reducing maintenance and minimise downtime.

- Bearing Assembly. The maintenance friendly bearing assembly has heavy-duty roller bearings, robust housings, and a massive shaft convert from AlphaFlo V sereis vertical sump pump.

- Shaft sealing. Cantilever vertical pump no shaft seal requirement.

- Metal and rubber lined pump. Totally interchangeable thick rubber or hardened metal liner

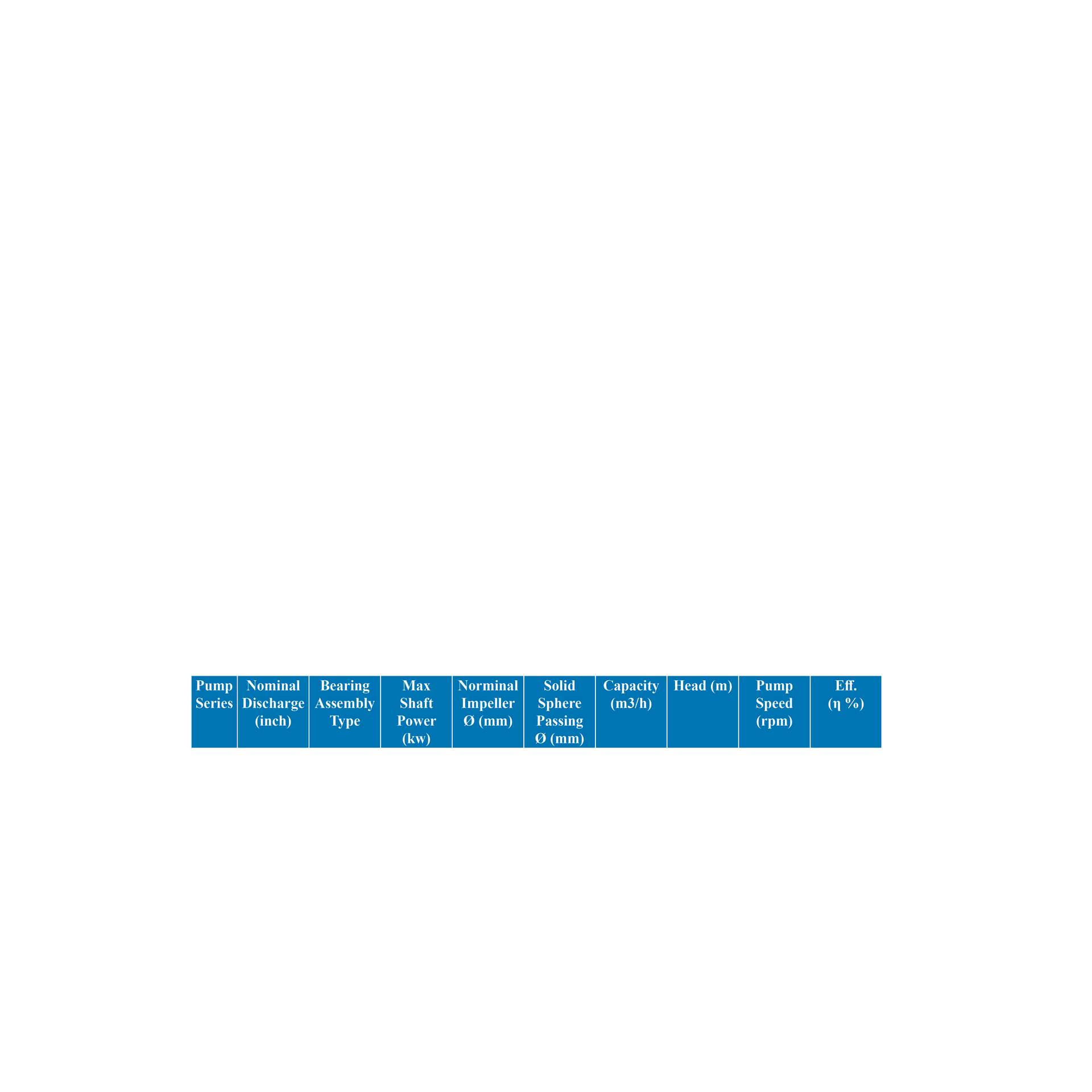

Specifications:

- Size range (discharge) 2” to 18”

- Capacities to 575 m3/hr

- Heads to 30 m

Typical applications:

- Froth

- Talings

- Flotation

- Thickening

- Sugar cane refining

Hard Rock Mining

- Mine Dewatering

- Mill Discharge

- Concentrator

- Agglomerators

- Tailings

Mineral Processing

- Coal Washing

- Phosphoric Acid Slurry

- Sand Seperation

Industrial Processing

- Sugar Industry

- Chemical Process

- Pulp Paper

- Fuel Gas Desulfurization

About slurry pump technique issue,slection,inquiry,please don't hesitate to contact us.