AlphaFlo®

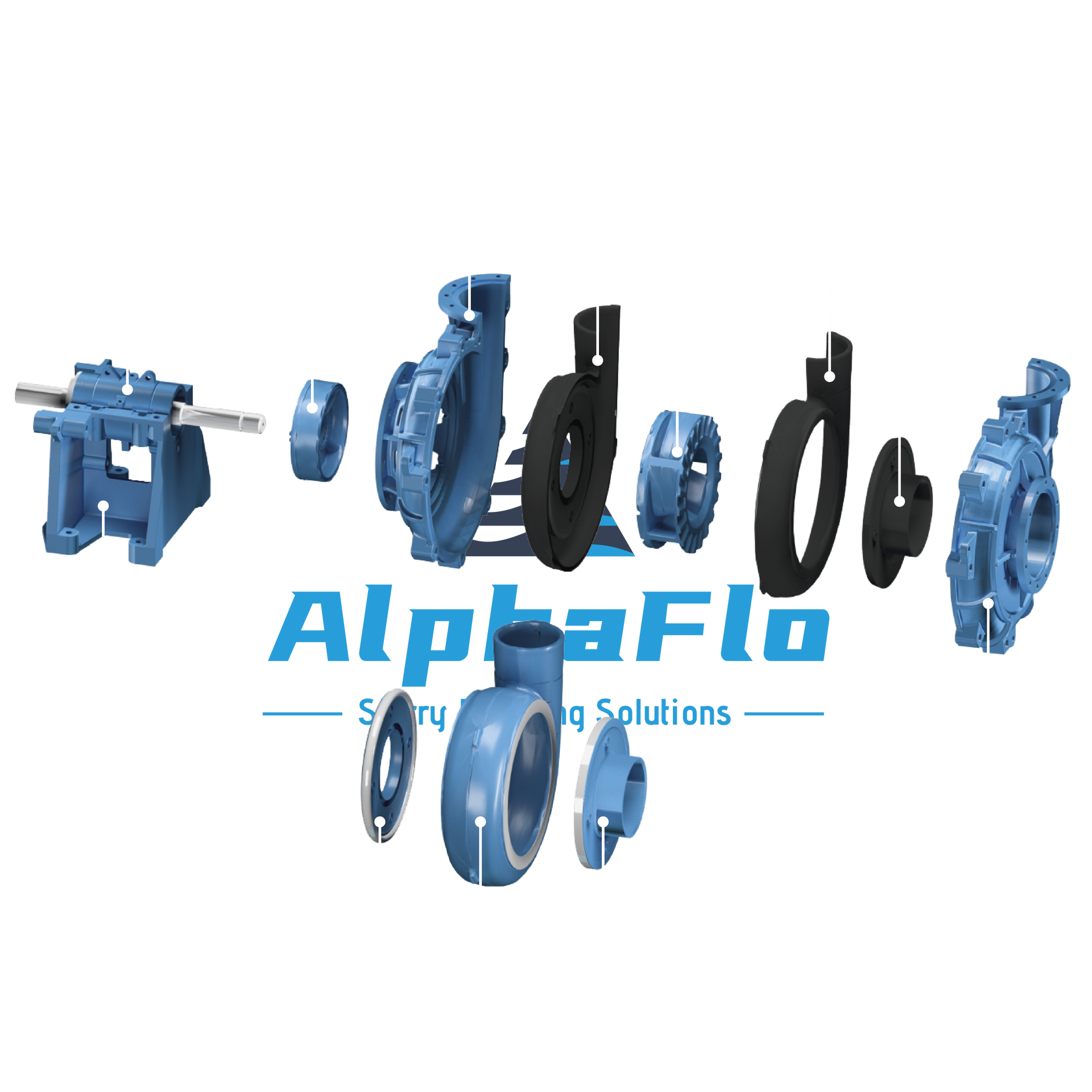

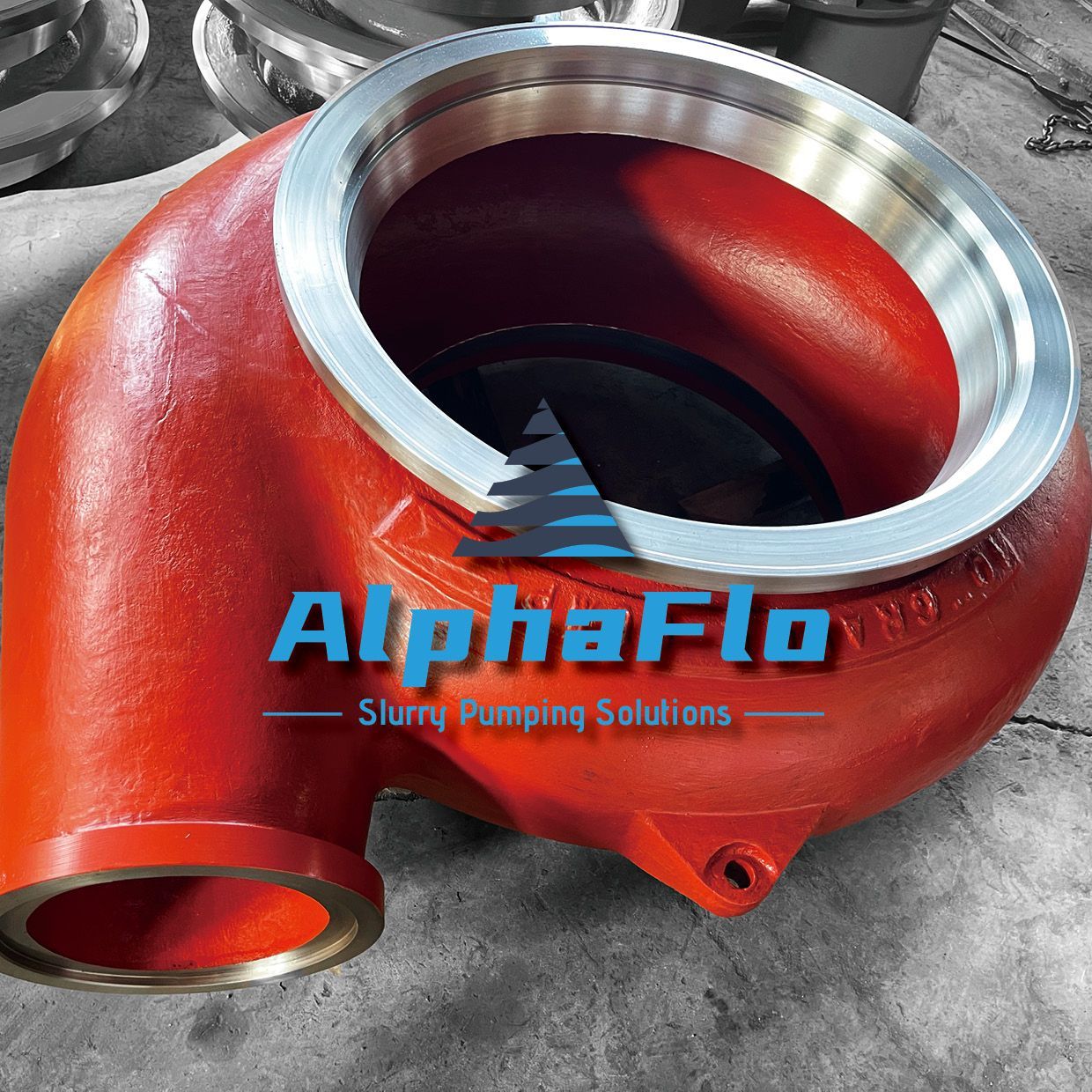

Centrifugal Slurry Pump Parts

AlphaFlo® aftermarket OEM Weir Warman L and M series centrifugal slurry pump spare parts

AlphaFlo® supply and for sale replacing Warman L and M type horizontal rubber & metal lining centrifugal slurry pump parts :

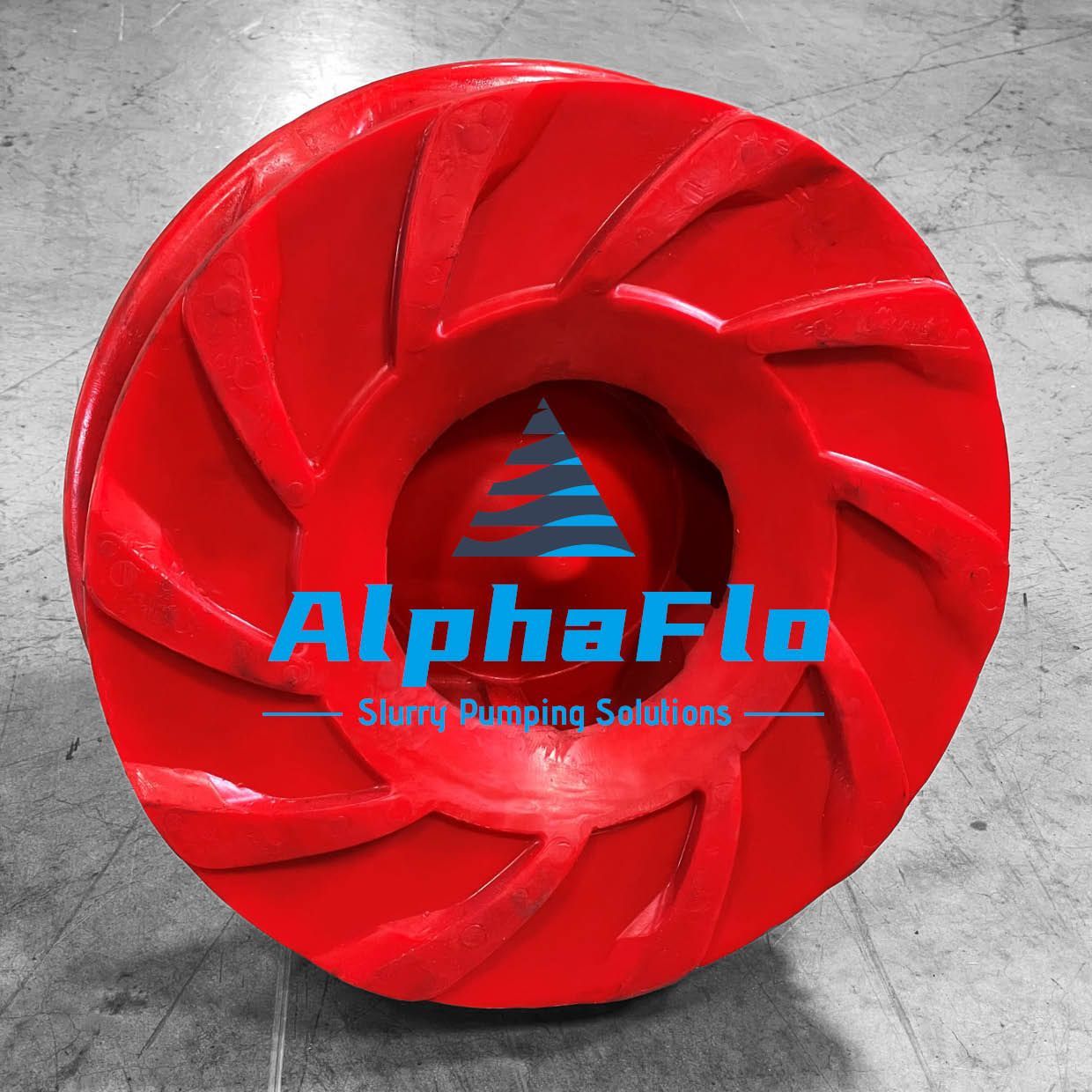

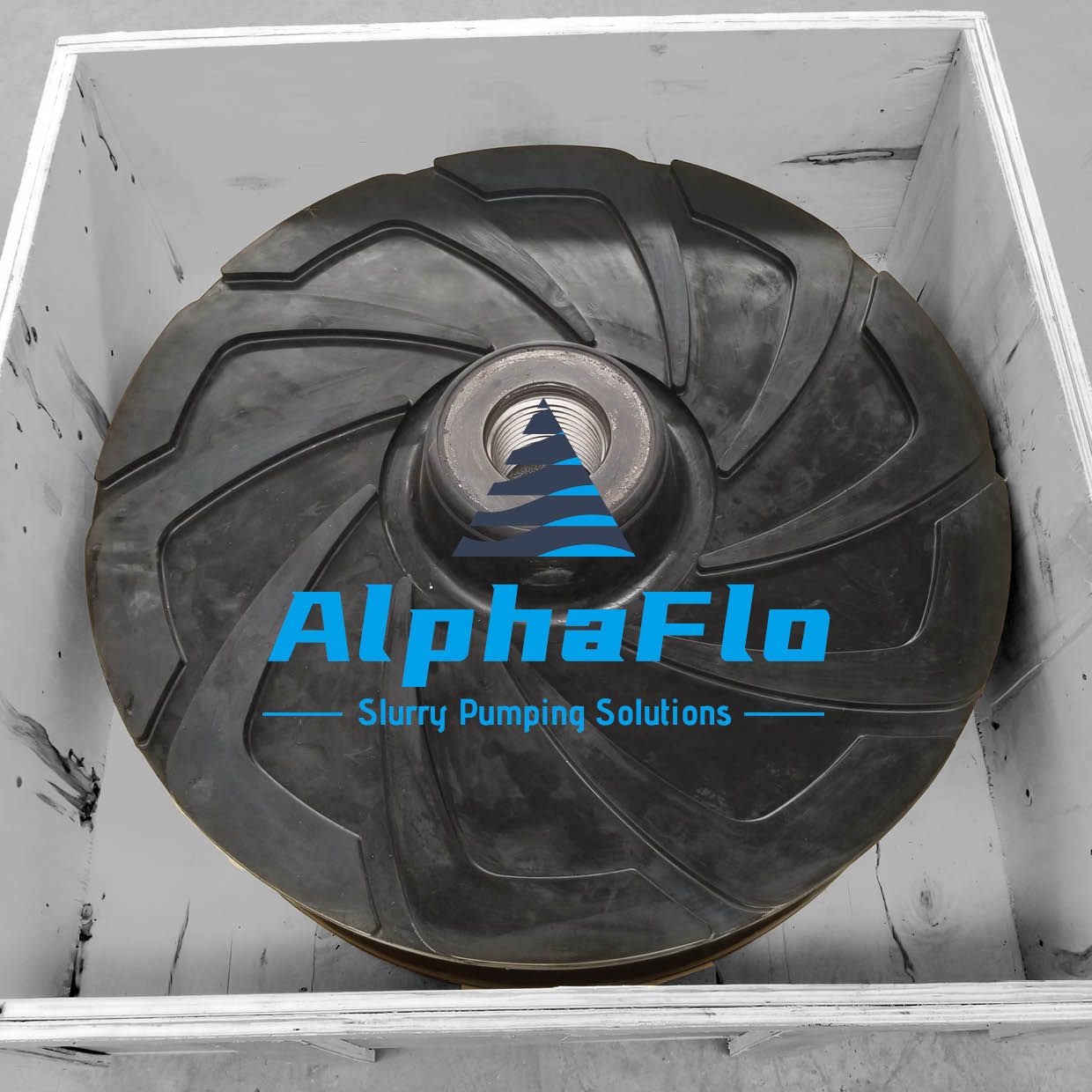

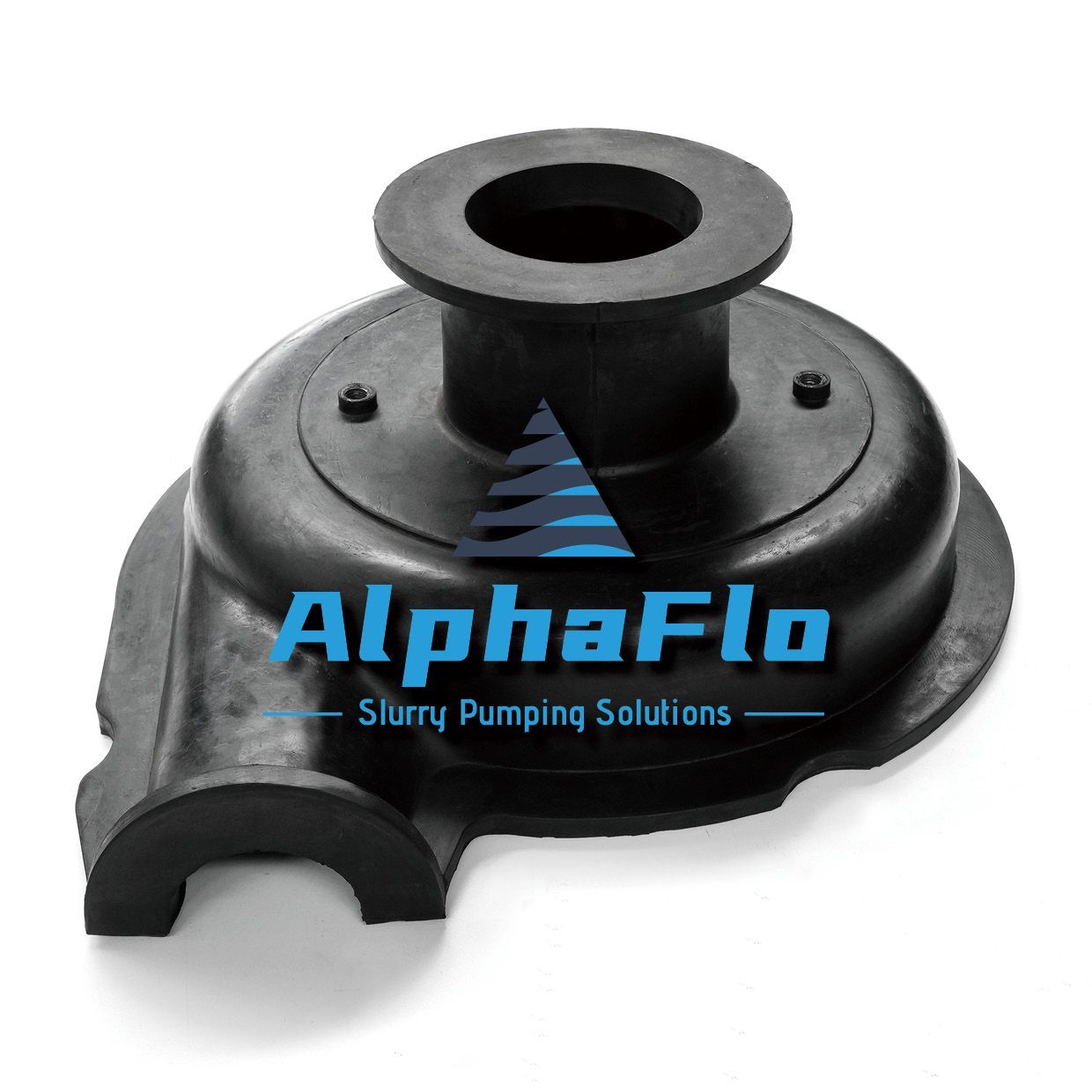

Wet end parts: Impeller,volute liner,throatbush,frame plate liner insert

Engineering parts: Cover Plate/Frame Plate,Base

Driving end: Cartridge style bearing assembly

Shaft seal parts: expeller, expeller ring,stuffing box,shaft sleeve,lantern ring/restrictor,gland,packing,

Seals&O Ring,V Rings: shaft sleeve o ring,expeller ring seal,stuffing box seal,volute cover seal,volute frame seal,discharge joint ring,intake joint ring.

Features:

- Casing. Two halves radially split casing with minimum casing bolts reducing maintenance and minimise downtime.

- Impeller & liner. Thick elastomer or alloy bolt-in liners provide superior corrosion resistance plus offer ease of liner change-out and intermixability to reduce over all maintenance costs and maximize wear life.

- Bearing Assembly. removeable cartridge style grease luburicated bearing assembly can be replaced with the base.Also oil lubricated heavy duty bearing assemblies available.

- Shaft sealing

- centrifugal seal (dry-seal,elimination gland seal water),common gland seal and mechanical seal.

Declaration : All OEM

Warman pump &

Warman pump parts name,number and descriptions are for reference only. AlphaFlo's slurry pump parts

interchangeable with OEM but AlphaFlo not affilicated with OEM.

List of OEM Pump Type & Models Interchangeable

| OEM WEIR | WARMAN | WARMAN |

|---|---|---|

| WARMAN PUMP | L&M SEREIS | L&M SEREIS |

| WARMAN PUMP | SLURRY PUMP | SLURRY PUMP |

| WARMAN PUMP | 20 AL | 20 A-L |

| WARMAN PUMP | 50 BL | 50 B-L |

| WARMAN PUMP | 75 CL | 75 C-L |

| WARMAN PUMP | 100 DL | 100 D-L |

| WARMAN PUMP | 150 EL | 150 E-L |

| WARMAN PUMP | 10/8 EM | 10/8 E-M |

| WARMAN PUMP | 10/8 EEM | 10/8 EE-M |

| WARMAN PUMP | 10/8 FM | 10/8 F-M |

| WARMAN PUMP | 10/8 FFM | 10/8 FF-M |

| WARMAN PUMP | 10/8 RM | 10/8 R-M |

| WARMAN PUMP | 12/10 EM | 12/10 E-M |

| WARMAN PUMP | 12/10 EEM | 12/10 EE-M |

| WARMAN PUMP | 12/10 FM | 12/10 F-M |

| WARMAN PUMP | 12/10 FFM | 12/10 FFM |

| WARMAN PUMP | 12/10 RM | 12/10 R-M |

| WARMAN PUMP | 300 FL | 300 F-L |

| WARMAN PUMP | 300 FFL | 300 FF-L |

| WARMAN PUMP | 300 RSL | 300 RS-L |

| WARMAN PUMP | 350 FL | 350 F-L |

| WARMAN PUMP | 350 FFL | 350 FF-L |

| WARMAN PUMP | 350 SL | 350 S-L |

| WARMAN PUMP | 400 GL | 400 G-L |

| WARMAN PUMP | 400 STL | 400 S-TL |

| WARMAN PUMP | 450 GL | 450 G-L |

| WARMAN PUMP | 450 STL | 450 ST-L |

| WARMAN PUMP | 500 STL | 500 ST-L |

| WARMAN PUMP | 650 TUL | 650 TU-L |

Rubber Wet End Parts

- Impeller 147&127&145

- Frame Plate Liner - 036&043

- Cover Plate Liner - 017&018

- Throatbush- 083

- FPL Insert - 041

Mechanical End

- Base - 003

- Frame -032 & Cover Plate - 013

- Bearing assembly - 005

Slurry Pump Wet End Parts list-metal&rubber

| OEM WEIR | PUMP SIZE | FRAME TYPE | PUMP SERIES | OPTIONS | FPL INSERT | VOLUTE LINER | IMPELLER | THROATBUSH | MATERIALS |

|---|---|---|---|---|---|---|---|---|---|

| WARMAN PUMP | 20 | A | L | STANDARD | 175041A05 | AL2110A05 | 175056A05 | A05/A07/A33/A49/A51/A61 | |

| WARMAN PUMP | 50 | B | L | STANDARD | 32041A05 | BL5110A05 | 32056A05 | A05/A07/A33/A49/A51/A61 | |

| WARMAN PUMP | 75 | C/CC | L | STANDARD | 43041A05 | CL75110A05 | 43056A05 | A05/A07/A33/A49/A51/A61 | |

| WARMAN PUMP | 100 | D/DD | L | STANDARD | 64041A05 | DL10110A05 | 64056A05 | A05/A07/A33/A49/A51/A61 | |

| WARMAN PUMP | 150 | E/EE | L | STANDARD | 86041A05 | EL15110A05 | 86056A05 | A05/A07/A33/A49/A51/A61 | |

| WARMAN PUMP | 10X8 | E/EE/F/FF/R | M | STANDARD | F8041MA05 | F8110A05 | F8147A05 | F8083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 10X8 | E/EE/F/FF/R | M | MECHANICAL SEAL | F8041MS1MA05 | F8110A05 | F8147A05 | F8083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 10X8 | E/EE/F/FF/R | M | HI-SEAL | F8041HS1A05 | F8110A05 | F8147A05 | F8083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 12X10 | E/EE/F/FF/R | M | STANDARD | F10041MA05 | F10110A05 | F10147A05 | F10083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 12X10 | E/EE/F/FF/R | M | HI-SEAL | F10041HS1A05 | F10110A05 | F10147A05 | F10083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 300 | F/FF/R | L | STANDARD | S30041MA05 | SL30110A05 | SL30147A05 | SL30083MA05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 350 | FF/S | L | STANDARD | S35041MA05 | SL35110A05 | SL35147A05 | SL35083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 400 | G/ST | L | STANDARD | T40041MA05 | TL40110A05 | STL40147A05 | TL40083MA05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 450 | G/ST | L | STANDARD | T45041MA05 | TL45110A05 | STL45147A05 | TL45083MA05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 500 | ST | L | STANDARD | TL50041A05 | TL50110A05 | STL50147A05 | TL50083A05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 550 | TU | L | STANDARD | U55041A05 | UL55110A05 | TUL55147A05 | UL55083MA05 | A05/A07/A33/A49/A51/A61 |

| WARMAN PUMP | 650 | U | L | STANDARD | U18041MA05 | UL65110A05 | TUL65147A05 | UL65083MA05 | A05/A07/A33/A49/A51/A61 |

| OEM WEIR | PUMP SIZE | FRAME TYPE | PUMP SERIES | C.P. LINER | F.P.LINER | FPL INSERT | IMPELLER | THROATBUSH | MATERIALS |

|---|---|---|---|---|---|---|---|---|---|

| WARMAN PUMP | 20 | A | L | 175017R55 | 175036R55 | 175052R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | ||

| WARMAN PUMP | 50 | B | L | 32017MR55 | 32036R55 | 32052R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | ||

| WARMAN PUMP | 75 | C/CC | L | 43017MR55 | 43036MR55 | 43052R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | ||

| WARMAN PUMP | 100 | D/DD | L | 64017MR55 | 64036MR55 | 64114R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | ||

| WARMAN PUMP | 150 | E/EE | L | 86017MR55 | 86036MR55 | 86127R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | ||

| WARMAN PUMP | 10/8 | E/EE/F/FF/R | M | F8018R55 | F8036MR55 | F8147R55 | F8083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | |

| WARMAN PUMP | 10/8 | E/EE/F/FF/R | M | F8018R55 | F8036HS1R55 | F8147R55 | F8083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | |

| WARMAN PUMP | 10/8 | E/EE/F/FF/R | M | F8018R55 | F8036MS1MR55 | F8147R55 | F8083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | |

| WARMAN PUMP | 12/10 | E/EE/F/FF/R | M | F10018R55 | F10043R55 | F10041MR55 | F10047R55 | F10083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 12/10 | E/EE/F/FF/R | M | F10018R55 | F10043R55 | F10041HS1R55 | F10047R55 | F10083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 300 | F/FF/R | L | SL30018MR55 | SL30036MR55 | SL30147R55 | RSL30147R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 | |

| WARMAN PUMP | 350 | FF/S | L | SL35018MR55 | SL35043MR55 | SL35041MR55 | SL35147R55 | SL35083MR55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 400 | G/ST | L | TL40018MR55 | TL40043MR55 | T40041MR55 | STL40147R55 | STL40083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 450 | G/ST | L | TL45018MR55 | TL45043MR55 | TL45041MR55 | STL45147R55 | TL45083MR55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 500 | ST | L | TL50018R55 | TL50043R55 | TL50041R55 | STL50147R55 | TL50083R55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 550 | TU | L | UL55018MR55 | UL55043MR55 | U55041MR55 | TUL55147R55 | UL55083MR55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

| WARMAN PUMP | 650 | U | L | UL65018MR55 | UL65043MR55 | U18041MR55 | TUL65147R55 | UL65083MR55 | R08/R26/R33/R55/S01/S31/S42/U01/U38 |

Reliable OEM aftermarket slurry pump parts from AlphaFlo®, please don't hesitate to inquiry us.