AlphaFlo®

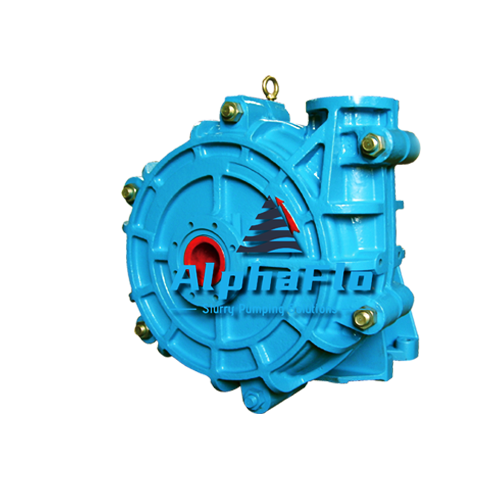

Coarse Tailings Slurry Pumps

Analog Warman HH type Slurry Pump Substitute Parts

AlphaFlo® supply wide range of OEM Weir Warman HH type high pressure slurry pump parts.

The OEM HH high head slurry pump were designed to produce high heads per stage at high pressures specially for long distance transport lines, which satisfy application duties with a single pump where others require multiple pumps in series

Features:

- Casing. Ductile iron fully lined casing provides durability, strength and long service life

- Impeller. Large diameter, slow turning, high efficiency impeller result in maximum wear life and lower operation cost.

- Bearing Assembly. removeable cartridge style grease luburicated bearing assembly can be replaced with the base.

- Shaft sealing. centrifugal seal (dry-seal,elimination gland seal water),common gland seal and mechanical seal.

Declaration : All OEM

Warman pump &

Warman pump parts name,number and descriptions are for reference only. AlphaFlo's slurry pump parts

interchangeable with OEM but AlphaFlo not affilicated with OEM.

| OEM WEIR | WARMAN | WARMAN |

|---|---|---|

| WARMA NPUMP | HH SEREIS | HH SEREIS |

| WARMA NPUMP | SLURRY PUMP | SLURRY PUMP |

| WARMA NPUMP | 1.5/1 CHH | 1.5/1 C-HH |

| WARMA NPUMP | 3/2 CHH | 3/2 C-HH |

| WARMA NPUMP | 3/2 CCHH | 3/2 CC-HH |

| WARMA NPUMP | 4/3 DHH | 4/3 D-HH |

| WARMA NPUMP | 4/3 DDHH | 4/3 DD-HH |

| WARMA NPUMP | 4/3 EHH | 4/3 E-HH |

| WARMA NPUMP | 4/3 EEHH | 4/3 EE-HH |

| WARMA NPUMP | 6/4 FHH | 6/4 F-HH |

| WARMA NPUMP | 6/4 FFHH | 6/4 FF-HH |

Slide title

Write your caption hereButton

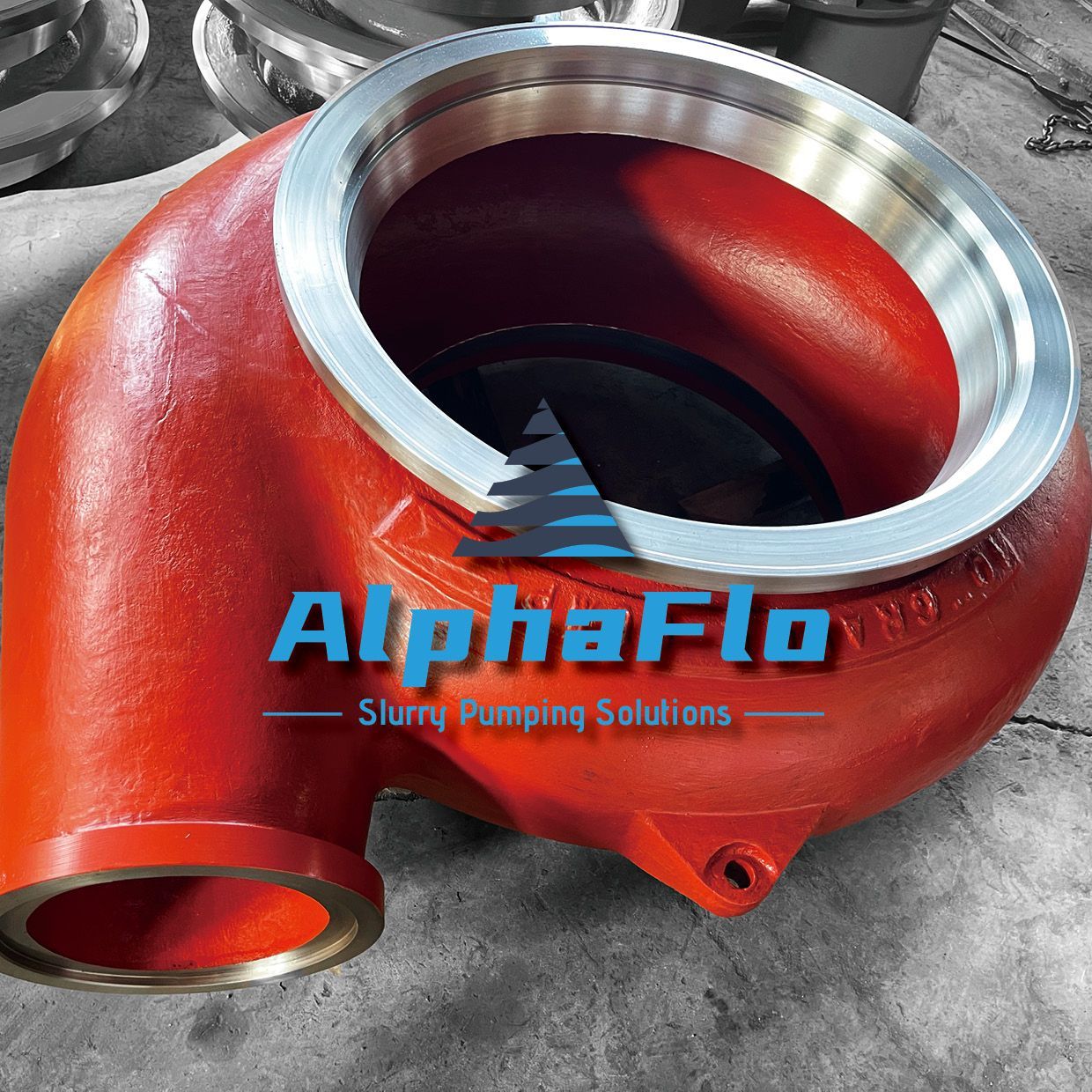

High Chrome White Iron

AlphaFlo metal slurry pump wear parts can handle the toughest abrasive applications, and adhere to all relevant ASTM standards. Our most popular 27-30% high chrome metallurgy has a guaranteed 600+ Brinell hardness. Also variety of alternative metallurgies are available for other corrosive applications. (A05/A07/A33/A49/A51/A61)

Slurry Pump Wet End Parts list-High Chrome Alloy

| OEM WEIR | PUMP SIZE | FRAME TYPE | PUMP SERIES | OPTIONS | FPL INSERT | VOLUTE LINER | IMPELLER | THROATBUSH | OTHERS |

|---|---|---|---|---|---|---|---|---|---|

| WARMAN PUMP | 1.5/1 | C/CC | HH | STANDARD | CH1041MA05 | CH1110A05 | CH1127A05 | ||

| WARMAN PUMP | 3/2 | D/DD | HH | STANDARD | DH2041MA05 | DH2110A05 | DH2147A05 | ||

| WARMAN PUMP | 4/3 | E/EE | HH | STANDARD | EH3041MA05 | EH3110A05 | EH3147A05 | EH3083A05 | |

| WARMAN PUMP | 6/4 | F/FF | HH | STANDARD | FH4041MA05 | FH4110A05 | FH4147A05 | FH4083A05 |

-

WHAT IS THE MAXIMUM PRESSURE RATING OF ALPHAFLO® H SERIES SLURRY PUMPS?

AlphaFlo® H series slurry pumps are pressure-rated up to 750 psi.

-

WHAT'S THE BIGGEST DIFFERENCE DURING ALPHAFLO® H SERIES AND A SERIES?

AlphaFlo® H and A sereis slurry pumps design with common frame,bearing cartridge,shaft sealing parts,the only difference is H series large diameter, slow turning, high efficiency impeller which result in maximum wear life and lower operation costs.

-

CAN ALPHAFLO® H SERIES SLURRY PUMP BE USED IN LONG DISTANCE SLURRY TRANSPORT?

ALPHAFLO® H series designed to produce high heads per stage at high pressures which result in be able to used for long distance transport lines, with a single pump where others require multiple pumps in series.

-

WHAT'S THE WARMAN A05 MATERIAL?

Weir Warman Alloy A05 is a wear resistant white that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy A05 is provided by the presence of hard carbides in the microstructure. Alloy A05 particularly suited to mild acidic duties where erosion resistance is required.

Most wet-end parts can be manufactured in alloy A05.The most common parts are as follows: Impellers, volute liners, throatbushes, plate liner inserts, bowls and doors.

-

WHAT'S THE DIFFERENCE BETWEEN ALPHAFLO® H SERIES AND OEM WEIR WARMAN® HH SLURRY PUMPS?

The Warman® HH range pump is the long proven of heavy duty high head lined slurry pumps. AlphaFlo® H series slurry pump parts equal with the OEM HH pumps have been rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance.

About slurry pump technique issue,slection,inquiry,please don't hesitate to contact us.