AlphaFlo®

Slurry Pump Parts

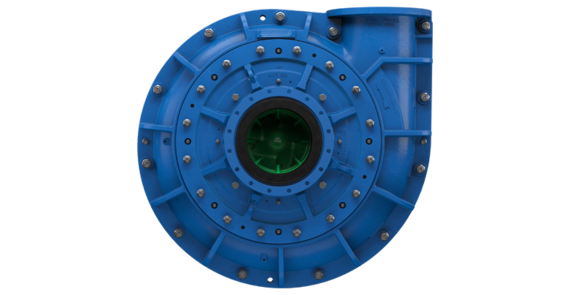

AlphaFlo high-quality interchangeable OEM Warman MCR pump parts

AlphaFlo® supply dimension interchangeable and material compatible OEM Warman MCR,MCR-M,MCU ,mill circuit duty slurry pump wear wet end parts.

The OEM

Weir company

Warman MC series mill circuit duty slurry pumps are designed for the most aggressive duties and provide excellent wear life and reliability.The mill circuit pumps easily manage large size particles in highly abrasive slurries and are specifically designed for the most severe slurry applications such as ball and

SAG mill cyclone feed plus water-flush crushing in mineral processing plants. Unique design and wear evaluation software promotes high efficiency and optimum life via incorporation of the latest in hypereutectic alloy and elastomer technology, extending wear life in

highly abrasive and

corrosive slurries.

- Warman MCR pump

- Thick

elastomer liners inside ductile iron outer casing with

metal impeller and metal or elastomer

throatbush and

frame plate liner insert

- Warman MCR-M pump

- High chrome iron metal liners inside ductile iron outer casing with metal impeller, throatbush and frame plate liner insert

- Warman MCU pump

- all metal unlined high chrome iron casing with metal impeller, throatbush and frame plate liner insert

Pump Type & Models

| Pump Type | Pump Model | Size/in | Frame 1 | Frame 2 |

|---|---|---|---|---|

| MCR | 125 | 6X5 | EEAM | |

| MCU | 125 | 6X5 | EEAM | |

| MCR | 150 | 8X6 | EE | |

| MCU | 150 | 8X6 | EE | |

| MCR | 200 | 10X8 | FF | M100 |

| MCU | 200 | 10X8 | FF | M100 |

| MCR | 250 | 12X10 | FF | M100 |

| MCU | 250 | 12X10 | FF | M100 |

| MCR | 300 | 14X12 | GGAM | M120 |

| MCU | 300 | 14X12 | GGAM | M120 |

| MCR | 350 | 16X14 | TU | M120 |

| MCU | 350 | 16X14 | TU | M120 |

| MCR | 400 | 18X16 | TU | M150 |

| MCR | 450 | 20X18 | TU | M150 |

| MCR | 550 | 26X22 | U | M180 |

| MCR | 650 | 30X26 | U | M200 |

| MCR | 750 | 36X30 | V | M240 |

Rubber & Elastomers

AlphaFlo offer a wide variety of natural rubber and synthetic elastomers for the majority of slurry pump wetted parts provide longer life and abrasion resistance in a variety of applications.

- Natural Rubber

- Neoprene

- Hypalon

- EPDM

- Nitrile

- Butyl

- Urethane

High Chrome White Iron

AlphaFlo cast slurry pump wear parts can handle the toughest abrasive applications, and adhere to all relevant ASTM standards. Our most popular 27-30% high chrome metallurgy has a guaranteed 600+ Brinell hardness. Also variety of alternative metallurgies are available for more corrosive applications.

| OEM WEIR | PUMP SERIES | PUMP SIZE | COVER PLATE LINER | FPL INSERT | FRAME PLATE LINER | THROATBUSH | IMPELLER |

|---|---|---|---|---|---|---|---|

| WARMAN PUMP | MCR | 150 | EMCR15018R55 | EMC15041R55 | EMCR15043R55 | EMC15083R55 | FMC15145EL1A05 |

| WARMAN PUMP | MCR | 200 | GMCR20018R55 | GMC20041R55 | GMCR20043R55 | GMC20083R55 | GMC20145EL1A05 |

| WARMAN PUMP | MCR | 250 | GMCR25018R55 | GMC25041R55 | GMCR25043R55 | GMC25083R55 | GMC25145EL1A05 |

| WARMAN PUMP | MCR | 300 | GAMMCR30018R55 | GAMMCR30041R55 | GAMMCR30043R55 | GAMMCR30083R55 | M120MC30147A05 |

| WARMAN PUMP | MCR | 350 | TUMCR35018R55 | M120MC35041R55 | TUMCR35043R55 | TUMC35083R55 | M120MC35147A05 |

| WARMAN PUMP | MCR | 400 | UMCH40018R55 | UMCH40041R55 | UMCH40043R55 | UMCH40083R55 | TUMC40147A08 |

| WARMAN PUMP | MCR | 450 | UMCR45018R55 | UMC45041R55 | UMCR45043R55 | UMC45083R55 | TUMC45147A08 |

| WARMAN PUMP | MCR | 550 | UMC55018R55 | UMCR55041R55 | UMC55043R55 | UMCR55083R55 | UMC55145EL1A08 |

| WARMAN PUMP | MCR | 650 | UMCH65018R55 | UMC65041R55 | UMCH65043R55 | UMC65083R55 | UMC65145EL1A08 |

-

WHAT'S THE DIFFERENCE OF OEM WARMAN® MCR,MCR-M AND MCU SLURRY PUMPS?

They are mill circuit pumps and easily manage large size particles in highly abrasive slurries and are specifically designed for the most severe slurry applications such as ball and SAG mill cyclone feed plus water-flush crushing in mineral processing plants.

- Warman MCR pump – thick elastomer liners inside ductile iron outer casing with metal impeller and metal or elastomer throatbush and frame plate liner insert

- Warman MCR-M pump – high chrome iron metal liners inside ductile iron outer casing with metal impeller, throatbush and frame plate liner insert

- Warman® MCU pump – all metal unlined high chrome iron casing with metal impeller, throatbush and frame plate liner insert

-

WHAT'S THE OEM WARMAN® PUMPS BASIC PART NUMBER?

- Each Warman pump part has a unique name and a three-digit Basic Part Number.Parts with the same name have the same Basic Part Number, regardless of pump size.For example, the bearing assembly of every Warman pump has the Basic Part Number 005.

- Additional letters and numbers are added before and after the Basic Part Number to further define a component part of a particular pump,For example, Part Number E4110A05 identifies the impeller to fit the casing of the 6/4E-AH pump, "A05" is the part material.

-

WHAT MATERIALS WEIR WARMAN® PUMP PARTS MADE OF?

- Weir Warman pump parts mainly made of metal or rubber.

- Metal of high chrome white iron abrasion & corrosion resistant (A05 & A07 & A33 & A49 & A51 & A61) for impeller & liner, stainless steel (C21 & C23 & C26 & C55 ) for shaft sleeve & lantern ring or wet end parts,engineering steel (E02 & E62 & E05 & E65) for shaft and fasten bolts & nuts.

- Rubber of abrasion resistance natrual rubber R55 for impeller & wear liner,synthetic elastomers-Neoprene (S42) & Hypalon (S31) & EPDM (S01) & Nitrile (S10) & Polyurethane (U01 & U38 ) for impeller & liner & O ring & joint seals.

- Combinated material: J04 & J05 & J21 & J31 ceramic & chrome & tungsten carbide coated steel.

-

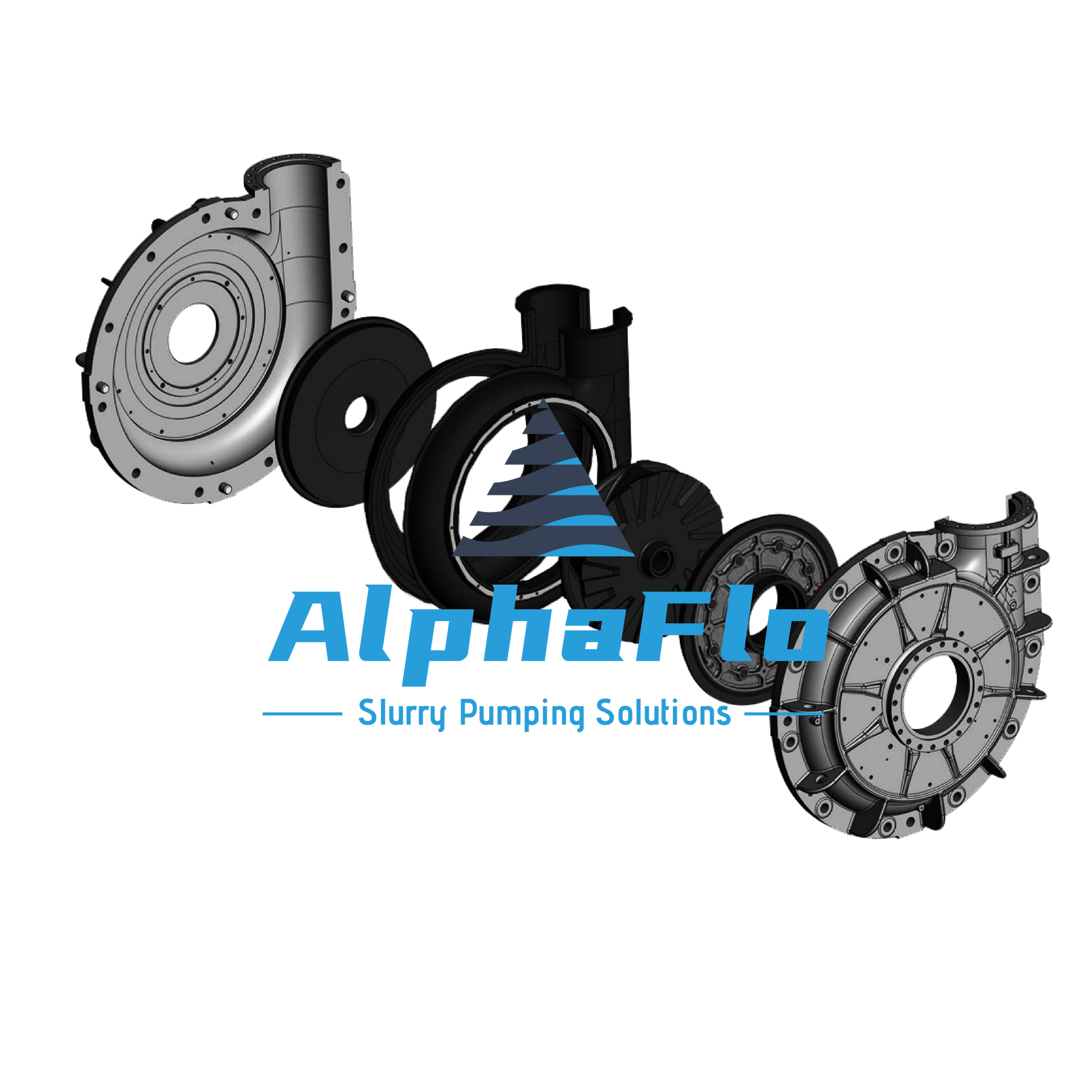

WHAT ARE THEY OEM WARMAN® SLURRY PUMPS WET END PARTS AND WEAR PARTS?

- Generally a Weir Warman slurry pump consist 30~40 units components and could be subdivided into the wet end,the mechanical end and the support end.

- The wet end clearly awared the slurry pass through parts,such as the impeller,volute liner,back liner and throatbush-the most wear parts of abrasion,corrosion and errosion.

- The mechanical portion of the pump includes the pump shaft, shaft sleeve, sealing arrangement, and the bearings assembly.

- The support end include the frame and casing plate.

- The wear parts include the wet end parts and some mechanical spares - shaft protection sleeve,shaft sleaing gland packing,lantern ring,lantern restrictor,expeller,expeller ring,stuffing box.

-

WHAT PUMP SPARE PARTS SHOULD I PURCHASE FROM ALPHAFLO® FOR STOCK IN FUTURE REPLACEING MY ORIGINAL WARMAN® SLURRY PUMPS DAMAGED SPARE?

- As above talked,slurry pump wet end parts and some shaft sealing parts is the wear parts which need replace in regular time.

- Managing and reducing the slurry pump wear is what AlphaFlo® does for our customers

- AlphaFlo® stock bulk regular slurry pump models wet ent parts for the shortest lead time to our customers.

-

CAN ALPHAFLO® SLURRY PUMP PARTS 100% ATAPATABLE TO MY GENUINE WARMAN PUMP WITH EQUIVALENT WORKING LIFE?

The Weir Minerals Group Warman® brand slurry pumps with 60 years history are the world standard for heavy duty slurry pumping solutoins. AlphaFlo® horizontal and vertical slurry pump parts have been rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit and material testing. All impellers have been performance tested to certify them against OEM Warman pump performance and equal service time.

Reliable OEM aftermarket slurry pump parts from AlphaFlo®, please don't hesitate to inquiry us.