AlphaFlo®

High quality reverse engineerd aftermarket OEM Warman pump parts from China

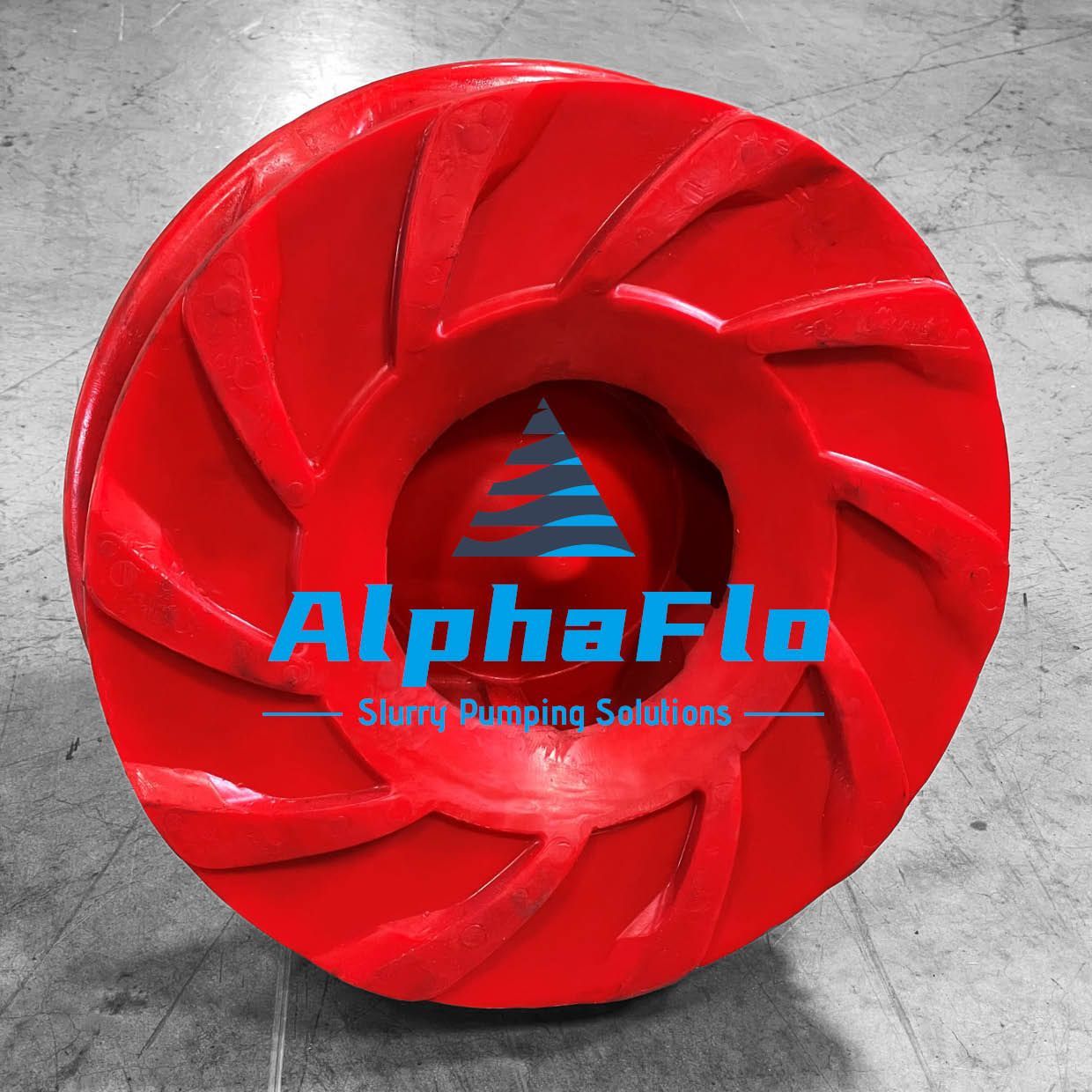

AlphaFlo® particularly work on the mining & construction & heavy industries of slurry pumpings and know the elemental of pumping solids slurry means that destructive wear on internal parts of an inevitable part of the life cycle of your slurry pumps.

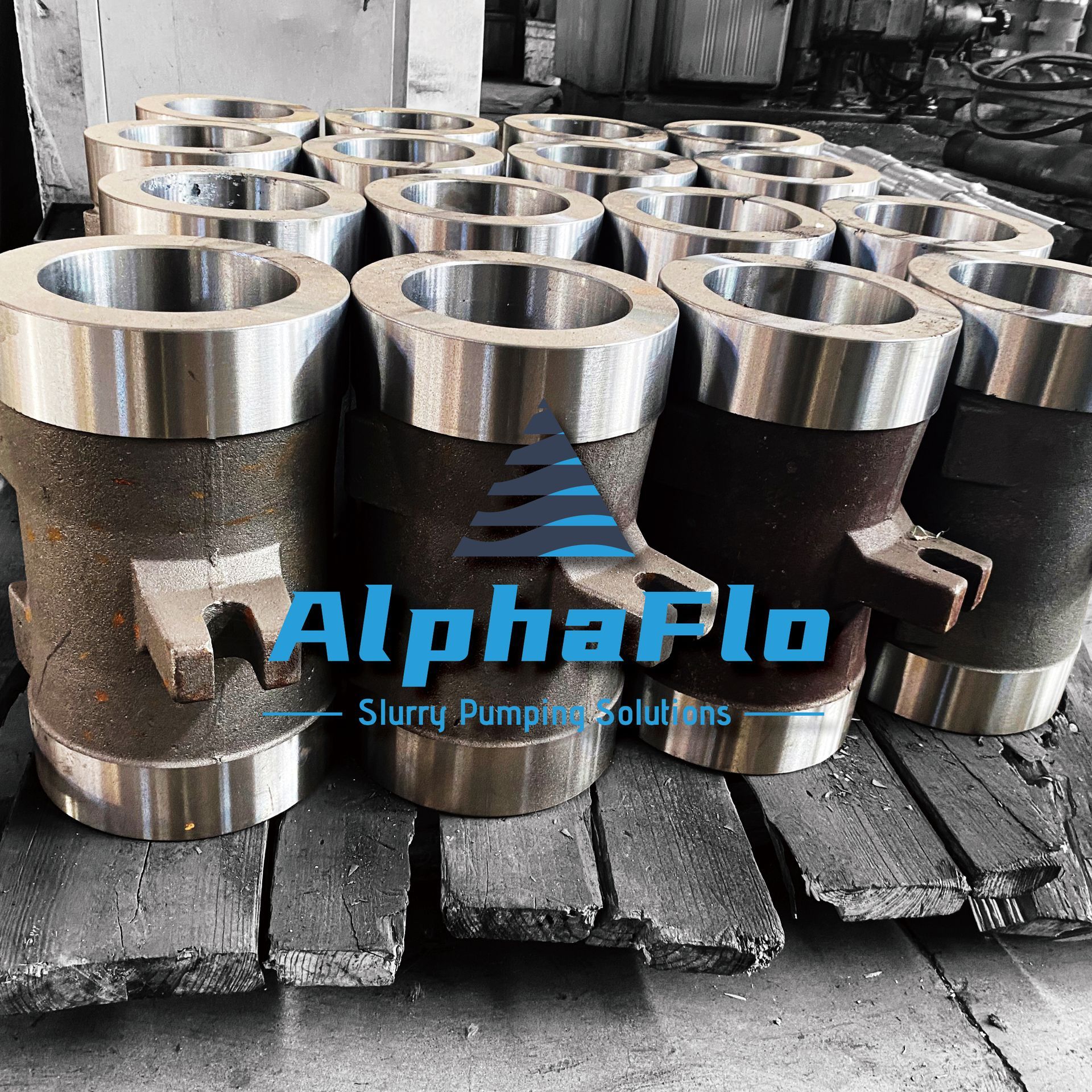

AlphaFlo® fabricates superior quality hardened metal and elastomer replacement parts fully compatible with Warman pumps, and gives value to customers through quality-to-price parts and lead times that are some of the lowest in the market. We stock volumn slurry pump parts, many of which are replaceable with Warman slurry pump parts. We maintain a global distribution network that stands ready to serve your process needs.

All parts compatible with the Warman slurry pumps have been rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance. AlphaFlo® manufactures replacement parts as we do our own: with technical expertise, quality, fair pricing, and product availability for the end users.

AlphaFlo

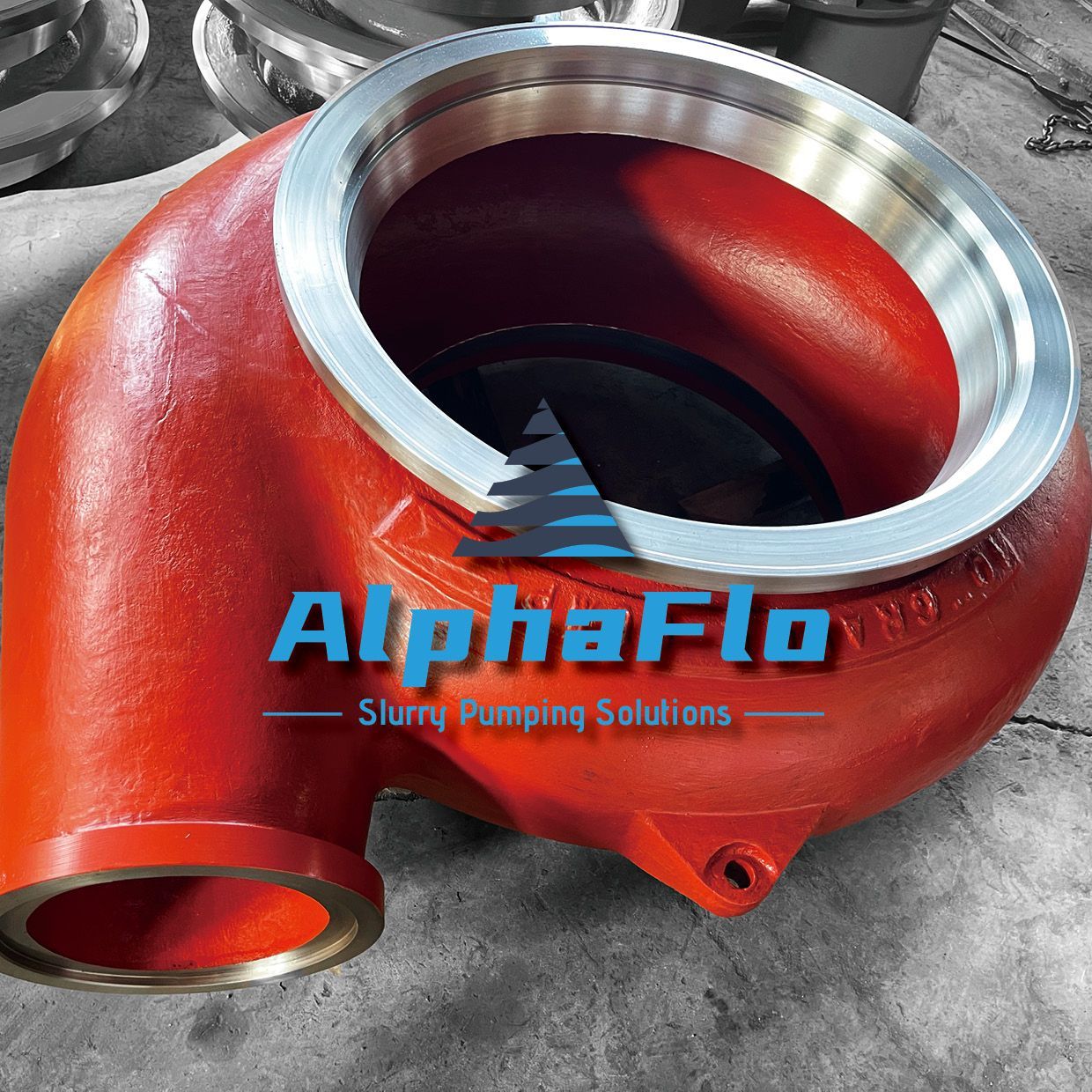

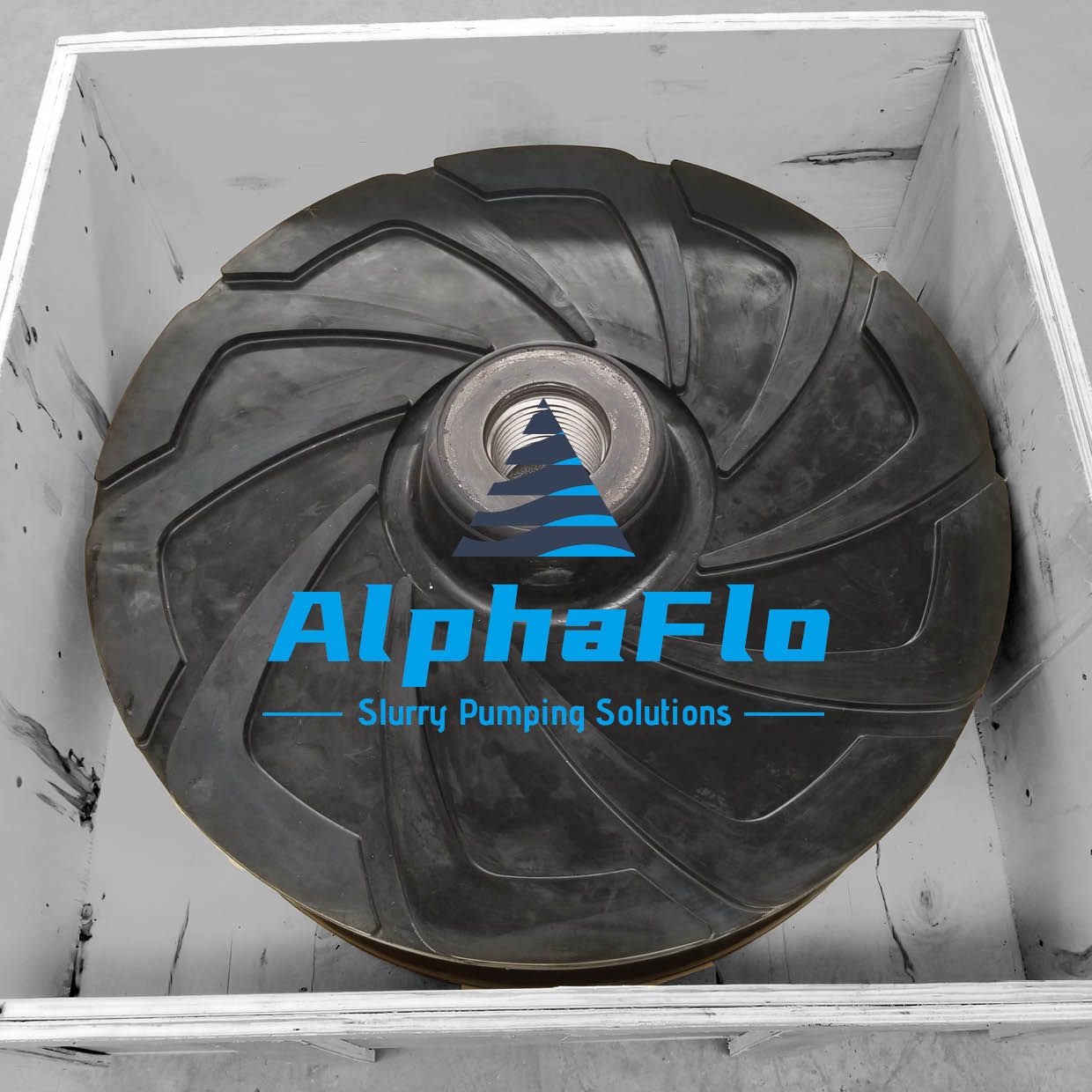

high chrome slurry pump parts manufactured to the highest degree of mechanical integrity through the use of accurate 3D modeling.

We use the latest SolidWorks and FaroArm technology to design precise parts at the beginning our manufacturing process, and inspect and verify those parts before shipping.

Materials

AlphaFlo cast slurry pump wear parts can handle the toughest abrasive applications, and adhere to all relevant ASTM standards. Our most popular 27-30% high chrome metallurgy has a guaranteed 600+ Brinell hardness. Also variety of alternative metallurgies are available for more corrosive applications.

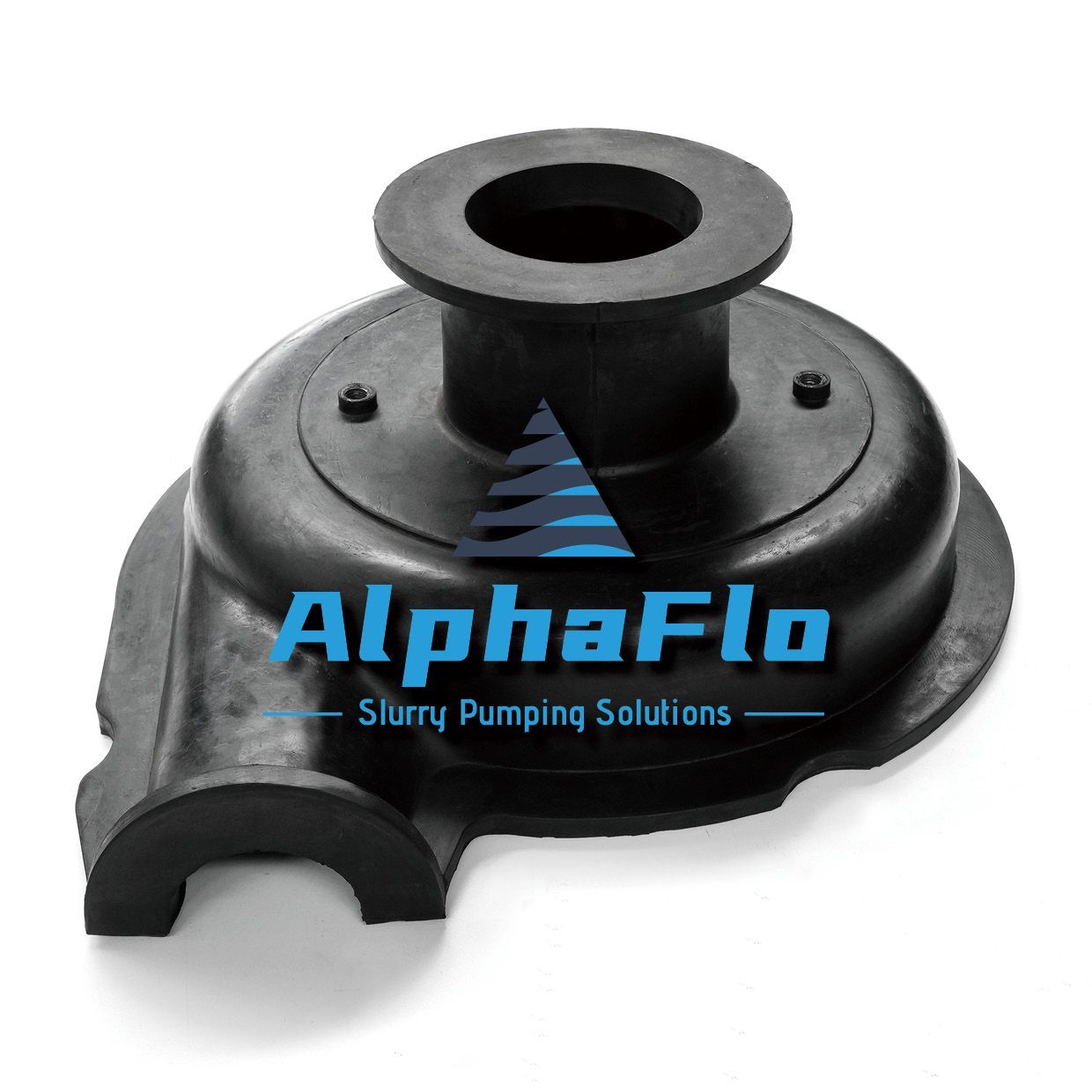

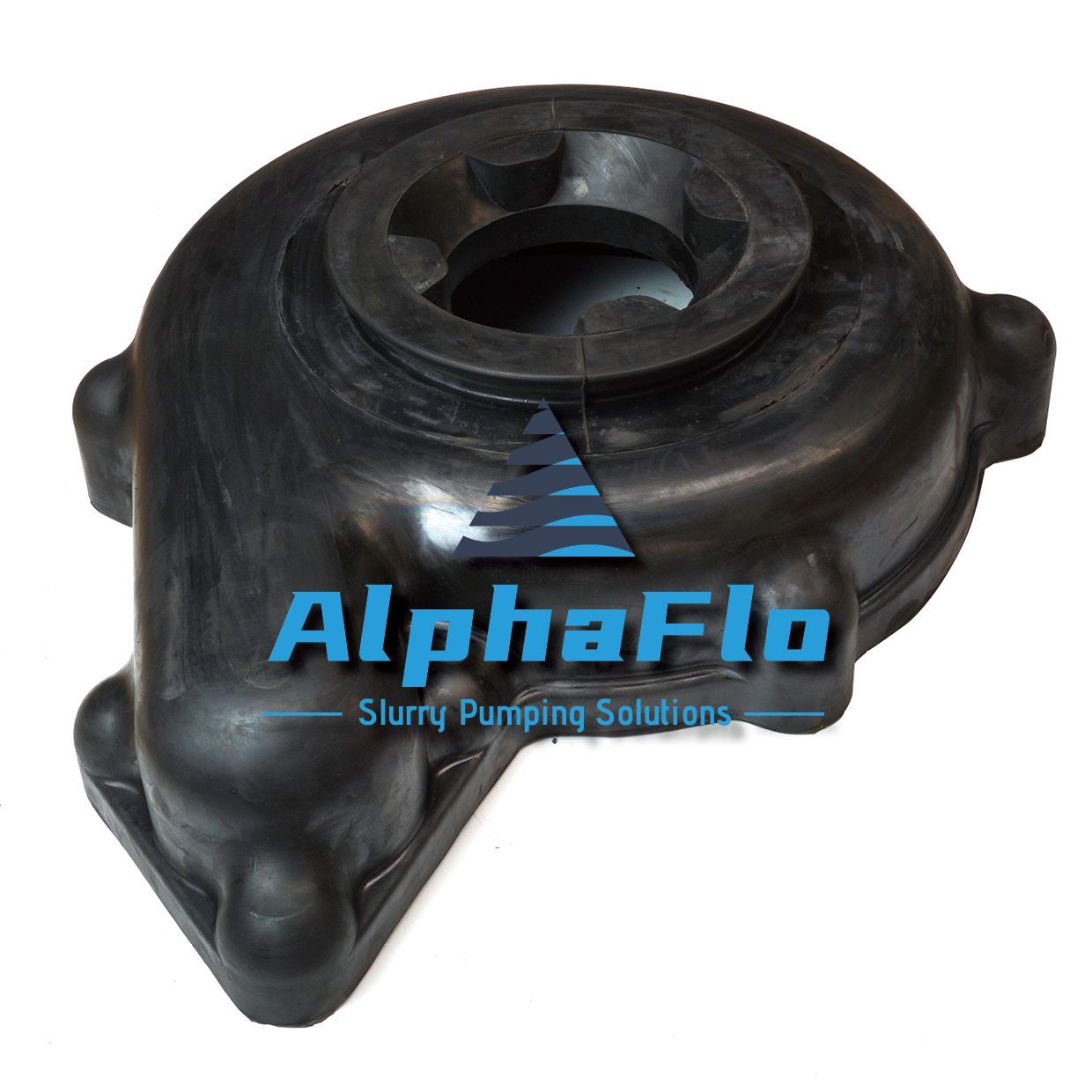

Rubber&Elastomer

| BASIC PART NUMBER | PART NAME | COMMON MATERIAL |

|---|---|---|

| 001 | ADJUSTING SCREW | E62 |

| 003 | BASE | G01/D21 |

| 004 | BEARING HOUSING | G01/D21 |

| 005 | BEARING ASSEMBLY | |

| 008 | BEARING SLEEVE | C21/C23/J04/J05 |

| 009 | BEARING | ZWZ/TIMKEN/SKF |

| 010 | LINER FACE SEAL | |

| 011 | CLAMP WASHER | E62 |

| 012 | CLAMP BOLT | E62 |

| 013 | COVER PLATE | G01/D21 |

| 015 | COVER PLATE BOLT | E62 |

| 017 | COVER PLATE LINER | R55/S31/S42 |

| 018 | COVER PLATE LINER | R55/S31/S42 |

| 019 | MOUNTING PLATE | |

| 021 | IMPELLER (2 VG-CHOKELESS) | A05/A07/A49/A51/A61 |

| 023 | COVER PLATE LINER STUD | E62 |

| 024 | END COVER | E65/D21 |

| 025 | SHIM SET | P05 |

| 026 | FRAME PLATE LINER INSERT STUD | E62 |

| 027 | END COVER SET SCREW | E62 |

| 028 | EXPELLER | A05/D21 |

| 029 | EXPELLER RING | A05/D21 |

| 032 | FRAME PLATE (ADAPTOR PLATE) | A05/A07/A61 |

| 034 | FRAME PLATE BOLT (ADAPTOR PLATE BOLT) | E62 |

| 036 | FRAME PLATE LINER | R55/S31/S42 |

| 039 | FRAME PLATE STUD (ADAPTOR PLATE STUD) | E62 |

| 041 | FRAME PLATE LINER INSERT (BACK LINER) | A05/A07/A61 |

| 043 | FRAME PLATE LINER | R55/S31/S42 |

| 045 | GLAND BOLT | E62 |

| BASIC PART NUMBER | PART NAME | COMMON MATERIAL |

|---|---|---|

| 046 | GREASE RETAINER | E65/G01 |

| 051 | IMPELLER (2 VOG) | |

| 052 | IMPELLER (3 VOG) | |

| 053 | IMPELLER (8 VOG) | |

| 056 | IMPELLER (8 VOG) | |

| 058 | IMPELLER (6 VCG) | |

| 060 | INTAKE JOINT RING | S01/S10 |

| 061 | LABYRINTH LOCKNUT | E62 |

| 062 | LABYRINTH | E65/G01 |

| 063 | LANTERN RING | C21/C23/P05/P50 |

| 064 | IMPELLER O RING | S01/S10 |

| 066 | MOTOR SUPPORT BOLT | E62 |

| 067 | NECK RING | C21/C23 |

| 070 | SHAFT KEY | E65 |

| 073 | SHAFT | E05 |

| 075 | SHAFT SLEEVE | C21/C23/J04/J05 |

| 076 | SHAFT SLEEVE | C21/C23/J04/J05 |

| 077 | SHAFT SLEEVE EJECTOR | C21/C23 |

| 078 | STUFFING BOX | A05/D21 |

| 079 | EXPELLER RING STUD | E62 |

| 081 | KEEPER PLATE | E65 |

| 083 | THROATBUSH | A05/A07/A49/A51/A61 |

| 085 | COTTER | E65 |

| 090 | LIP SEAL | S01/S10 |

| 092 | CASING | A05/A07/A49/A51/A61 |

| 102 | COLUMN | E02 |

| 108 | PISTON RING | E02 |

| 109 | SHAFT O RING | S01/S10 |

| 110 | VOLUTE LINER | A05/A07/A49/A51/A61 |

| BASIC PART NUMBER | PART NAME | COMMON MATERIAL |

|---|---|---|

| 111 | PACKING | Q05/Q21 |

| 116 | STRAINER | |

| 117 | SHAFT SPACER | C21/C23 |

| 118 | LANTERN RESTRICTOR | C21/C23 |

| 122 | SEAL-EXPELLER RING/STUFFING BOX | S01/S10 |

| 124 | VOLUTE COVER SEAL/DOOR SEAL | S01/S10 |

| 125 | VOLUTE FRAME SEAL/BOWL SEAL/BACK LINER SEAL | S01/S10 |

| 126 | GLAND CLAMP BOLT | E62 |

| 127 | IMPELLER (5 VOG) | A05/A07/A49/A51/A61 |

| 129 | CLAMP RING BOLT | E62 |

| 130 | FLANGE | A05/A07/A61 |

| 131 | BOWL | A05/A07/A61 |

| 134 | ADAPTOR PLATE CLAMP RING | E02 |

| 135 | DOOR CLAMP RING | E02 |

| 137 | IMPELLER (3 VCS) | A05/A07/A61 |

| 138 | GREASE CUP ADAPTOR | |

| 143 | SEAL HOLDER | |

| 145 | IMPELLER (4 VCG) | A05/A07/A49/A51/A61 |

| 147 | IMPELLER (4 VCG) | A05/A07/A49/A51/A61 |

| 153 | COLUMN CLAMP | |

| 154 | MANIFOLD | |

| 184 | FLINGER | |

| 191 | IMPELLER (TORQUE FLOW) | |

| 204 | MANIFOLD GASKET | |

| 206 | IMPELLER (5 V DOUBLE SIDED) | |

| 210 | HOUSING O RING | S01/S10 |

| 217 | O RING | S01/S10 |

| 221 | DISCHARGE FLANGE | E02 |

| 239 | IMPELLER RELEASE COLLAR | C21/C23 |

| Material Code | Description | Min Rrinell Hardness |

|---|---|---|

| ABRASION RESISTANT ALLOYS | ||

| A05 | Ultrachrome 27% CR | 650 |

| A07 | 15/3 Cr-Mo Iron | 650 |

| A49 | Ultrachrome 28% CR | 320 |

| A51 | Ultrachrome 35~45% CR | 400 |

| A61 | Hyperchrome 30% CR | |

| CORROSION RESISTANT ALLOYS | ||

| C21 | AISI 420C SS | 555 |

| C22 | 304 SS | |

| C23 | 316SS | 160 |

| C26 | 26CR 5NI SS (CD-4MCu) | 253 |

| C55 | Ferralium 255 | 250 |

| DUCTILE GREY IRON | ||

| D21 | 500-320-7 | |

| ENGINEERING STEEL | ||

| E02 | Carbon Steel (A36) Plain | |

| E62 | Carbon Steel (A36) Zinc Plated | |

| E05 | 1040,1141&1045 Steel | |

| E65 | 1040,1141&1045 Steel Zinc Plated | |

| GREY IRON | ||

| G01 | CAST IRON GRADE 200 | |

| G61 | CAST IRON GRADE 200 Zinc Plated | |

| COATINGS | ||

| J04 | C21/Ceramic Coated Alunina Oxide | |

| J05 | C21/Chrome Oxide Coating | |

| J21 | C21/Tungsten Carbide/Cobalt | |

| J22 | N22/Chrome Oxide Coating | |

| J24 | C23/Tungsten Carbide Coating |

| Material Code | Description | Min Rrinell Hardness |

|---|---|---|

| BRASS | ||

| K31 | 85/5/5/5 Leaded Gunmetal 836B | |

| ALUMINUMS | ||

| L02 | A303 Aluminum Alloy | |

| L12 | A356 Aluminum Alloy | |

| PLASTICS | ||

| P05 | Teflon (PTFE) | |

| P50 | Ryton R4 (Polyphenlyene Sulfide) | |

| GLAND PACKING | ||

| Q05 | PTFE lubricated fiberglass | |

| Q21 | Graphite Impregnated Aramid Fiber | |

| NATURAL RUBBERS | ||

| R08 | Black Nat,R55 Duro (obsolete) | |

| R26/510 | Standard Liner Material | |

| R33/520 | Soft Natural Rubber | |

| R55/505 | Soft Natural Rubber 50 Duro | |

| SYNTHETIC ELASTOMERS | ||

| S01 | Nordel (EPDM) 55 Duro (Seals) (valve sleeves) | |

| S10 | Nitrile | |

| S21 | Bromobutyl 65 Duro (Liners,Impellers) | |

| S31 | Hypalon 65 Duro | |

| S42/535/545 | Neoprene 50 Duro (Liners,Impellers) | |

| POLYURETHANES | ||

| U01 | Vibrathane B602 82 Duro | |

| U02 | Polyurethane 90 Duro | |

| U03 | Polyurethane 95 Duro | |

| U27 | Polyurethane 60 Duro | |

| U38 | Polyurethane 80Duro |

-

WHAT'S THE OEM WARMAN® PUMP BASIC PART NUMBER?

- Each Warman pump part has a unique name and a three-digit Basic Part Number.Parts with the same name have the same Basic Part Number, regardless of pump size.For example, the bearing assembly of every Warman pump has the Basic Part Number 005.

- Additional letters and numbers are added before and after the Basic Part Number to further define a component part of a particular pump,For example, Part Number E4110A05 identifies the impeller to fit the casing of the 6/4E-AH pump, "A05" is the part material.

-

WHAT MATERIALS WEIR WARMAN® PUMP PARTS MADE OF?

- Weir Warman pump parts mainly made of metal or rubber.

- Metal of high chrome white iron abrasion & corrosion resistant (A05 & A07 & A33 & A49 & A51 & A61) for impeller & liner, stainless steel (C21 & C23 & C26 & C55 ) for shaft sleeve & lantern ring or wet end parts,engineering steel (E02 & E62 & E05 & E65) for shaft and fasten bolts & nuts.

- Rubber of abrasion resistance natrual rubber R55 for impeller & wear liner,synthetic elastomers-Neoprene (S42) & Hypalon (S31) & EPDM (S01) & Nitrile (S10) & Polyurethane (U01 & U38 ) for impeller & liner & O ring & joint seals.

- Combinated material: J04 & J05 & J21 & J31 ceramic & chrome & tungsten carbide coated steel.

-

WHAT ARE THEY OEM WARMAN® SLURRY PUMP WET END PARTS AND WEAR PARTS?

- Generally a Weir Warman slurry pump consist 30~40 units components and could be subdivided into the wet end,the mechanical end and the support end.

- The wet end clearly awared the slurry pass through parts,such as the impeller,volute liner,back liner and throatbush-the most wear parts of abrasion,corrosion and errosion.

- The mechanical portion of the pump includes the pump shaft, shaft sleeve, sealing arrangement, and the bearings assembly.

- The support end include the frame and casing plate.

- The wear parts include the wet end parts and some mechanical spares - shaft protection sleeve,shaft sleaing gland packing,lantern ring,lantern restrictor,expeller,expeller ring,stuffing box.

-

WHAT PUMP SPARE PARTS SHOULD I PURCHASE FROM ALPHAFLO® FOR STOCK IN FUTURE REPLACEING MY ORIGINAL WARMAN® SLURRY PUMP DAMAGED SPARE?

- As above talked,slurry pump wet end parts and some shaft sealing parts is the wear parts which need replace in regular time.

- Managing and reducing the slurry pump wear is what AlphaFlo® does for our customers

- AlphaFlo® stock bulk regular slurry pump models wet ent parts for the shortest lead time to our customers.

-

CAN ALPHAFLO® SLURRY PUMP PART 100% ATAPATABLE TO MY GENUINE WARMAN PUMP WITH EQUIVALENT WORKING LIFE?

The Weir Minerals Group Warman® brand slurry pumps with 60 years history are the world standard for heavy duty slurry pumping solutoins. AlphaFlo® horizontal and vertical slurry pump parts have been rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit and material testing. All impellers have been performance tested to certify them against OEM Warman pump performance and equal service time.

Reliable OEM aftermarket slurry pump parts from AlphaFlo®, please don't hesitate to inquiry us.