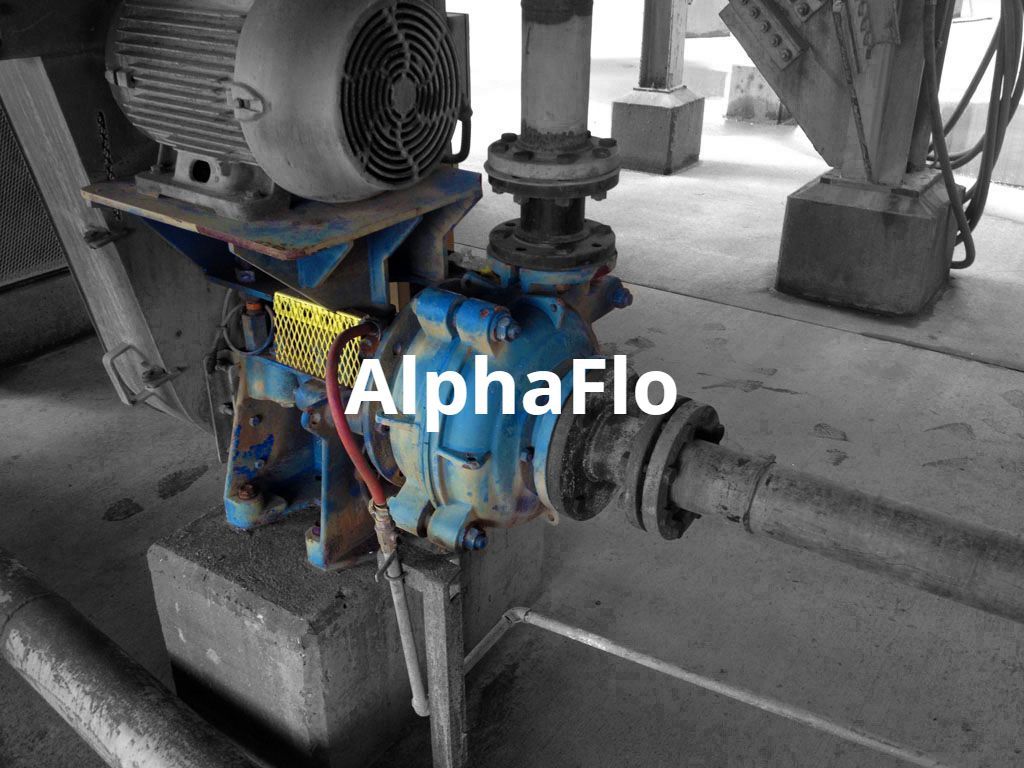

AlphaFlo®

Warman Centrifugal Slurry Pump

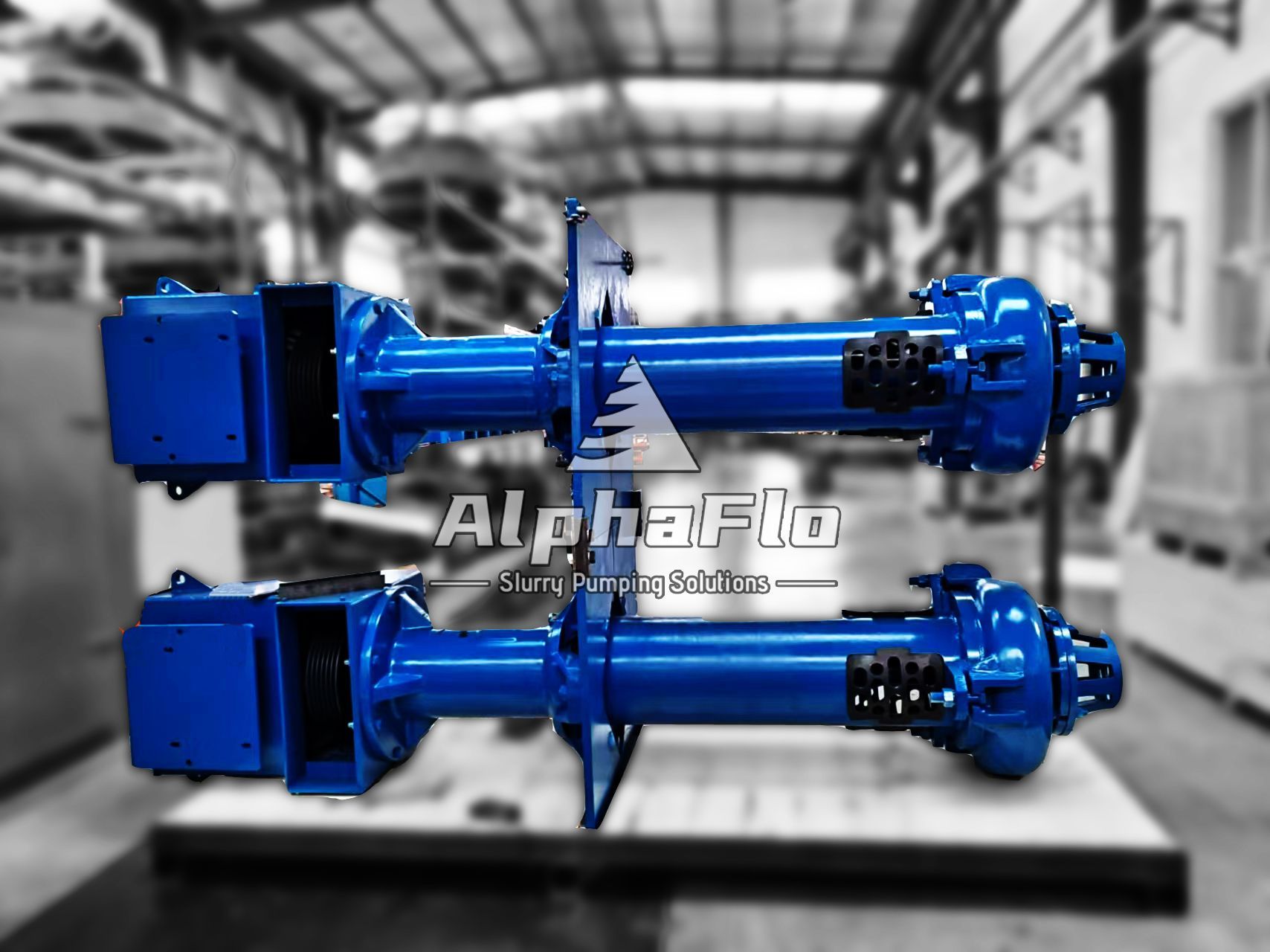

AlphaFlo® Alternative Warman pump series AH,HH,L,M,G,SP

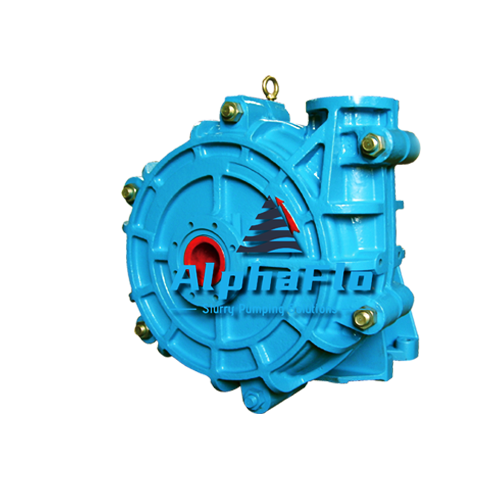

AlphaFlo® sale range of centrifugal slurry pump,froth pump and gravel pumps which totally replaceable with with Weir Warman pumps that widely applicated in mine dewatering,mill discharge,coal washing, sand seperation, tailings, sugar, pulp papar,concentrator with fair price and short leadtime.

AlphaFlo OEM converted slurry pump replacing parts made by rigorously reverse engineered using 2D 3D modeling. First article inspection involves comparison to OEM parts followed by fit and materials testing. All impellers have been performance tested to certify them against OEM performance.

- Ideal for highly abrasive & corrosive slurries.

- Constructed with various alloys (high chrome iron A05) & rubbers (R55) & polyurethane (U38) to reduce wear & minimise downtime.

| WARMAN | WARMAN | WARMAN | WARMAN | WARMAN | WARMAN | WARMAN | WARMAN |

|---|---|---|---|---|---|---|---|

| AH SEREIS | AHE SEREIS | AHF SEREIS | AHP&AHPP SEREIS | G&GH SEREIS | HH SEREIS | L&M SEREIS | SP&SPR SEREIS |

| SLURRY PUMP | SLURRY PUMP | FROTH PUMP | SLURRY PUMP | GRAVEL PUMP | SLURRY PUMP | SLURRY PUMP | SUMP PUMP |

| 1.5/1B-AH | 4/3C-AHE | 2C-AHF | 6/4EE-AHP | 6/4D-G | 1.5/1C-HH | 20A-L | 40PV-SP |

| 2/1.5B-AH | 4/3CC-AHE | 2CC-AHF | 8/6FF-AHPP | 6/4DD-G | 3/2C-HH | 50B-L | 40PV-SPR |

| 3/2C-AH | 6/4D-AHE | 3C-AHF | 10/8ST-AHP | 6/6E-G | 3/2CC-HH | 75C-L | 65QV-SP |

| 3/2CC-AH | 6/4DD-AHE | 3CC-AHF | 10/8T-AHPP | 6/6EE-G | 4/3D-HH | 100D-L | 65QV-SPR |

| 4/3C-AH | 8/6E-AHE | 3D-AHF | 12/10T-AHP | 8/6F-G | 4/3DD-HH | 150E-L | 100RV-SP |

| 4/3D-AH | 8/6EE-AHE | 3DD-AHF | 12/10T-AHPP | 8/6FF-G | 4/3E-HH | 10/8E-M | 100RV-SPR |

| 4/3DD-AH | 4D-AHF | 14/12T-AHP | 8/8F-G | 4/3EE-HH | 10/8EE-M | 150SV-SP | |

| 6/4D-AH | 4DD-AHF | 14/12T-AHPPP | 8/8FF-G | 6/4F-HH | 10/8F-M | 150SV-SPR | |

| 6/4DD-AH | 6E-AHF | 20/18TU-AHP | 10/8F-G | 6/4FF-HH | 10/8FF-M | 200SV-SP | |

| 6/4E-AH | 6EE-AHF | 20/18TU-AHPP | 10/8FF-G | 10/8R-M | 250TV-SP | ||

| 6/4EE-AH | 6F-AHF | 20/18U-AHP | 10/8S-G | 12/10E-M | |||

| 8/6E-AH | 6FF-AHF | 20/18U-AHPP | 10/8S-GH | 12/10EE-M | |||

| 8/6E-EAH | 8F-AHF | 12/10F-G | 12/10F-M | ||||

| 8/6F-AH | 8FF-AHF | 12/10F-G | 12/10FF-M | ||||

| 8/6FF-AH | 10ST-AHF | 12/10G-G | 12/10R-M | ||||

| 8/6R-AH | 10G-AHF | 12/10T-G | 300F-L | ||||

| 10/8F-AH | 12ST-AHF | 12/10G-GH | 300FF-L | ||||

| 10/8FF-AH | 12G-AHF | 12/10T-GH | 300RS-L | ||||

| 10/8ST-AH | 14TU-AHF | 14/12G-G | 350F-L | ||||

| 12/10F-AH | 14/12T-G | 350FF-L | |||||

| 12/10ST-AH | 16/14G-G | 350S-L | |||||

| 12/10G-AH | 16/14TU-GH | 400G-L | |||||

| 14/12ST-AH | 18/16G-G | 400ST-L | |||||

| 16/14G-AH | 18/16T-G | 450G-L | |||||

| 16/14TU-AH | 18/16TU-G | 450ST-L | |||||

| 20/18TU-AH | 18/16TU-GH | 500ST-L | |||||

| 20/18U-AH | 18/16U-GH | 650TU-L |

Declarations:

All Weir&Warman pump and parts models,numbers,description are only for reference..

AlphaFlo's slurry pump & parts interchangeable with OEM but not affilicated with OEM.