AlphaFlo®

Pompe Desolforazione Fumi

Puoi avvalerti della nostra esperienza, tecnologia e servizio di supporto per soddisfare le tue esigenze

requisito di trasporto del liquame come sempre.

AlphaFlo® D series especially designed for flue and gas desulfurization application for power plant, absorbing tower circling with easy maintenace and high efficiency.

(Intercambiabile con la pompa per liquami OEM Warman GSL Seires)

Caratteristiche:

- Back pull out design – Minimum number of larger diameter fasteners allows all rotating and wearing components, including the mechanical seal, to be inspected without disturbing the suction or discharge pipework.

- Lower corrosion in impellers – Specially formulated high chromium irons combined with optimum impeller vane designs minimize wear in the pumps.

- No corrosion in liners – Corrosion proof Natural rubber liners against acidic limestone&gypsum slurries, avoiding corrosion risks which can plague metal lined pumps, particularly when low pH slurries are left within the pumps when not operating.

- Long bearing and mechanical seal life – A large diameter shaft and short impeller overhand minimizes shaft deflection providing excellent conditions for the mechanical seal. Fully protected oversized heavy duty oil lubricated roller and taper roller bearings carry all the radial and thrust loads with unusually high service factors.

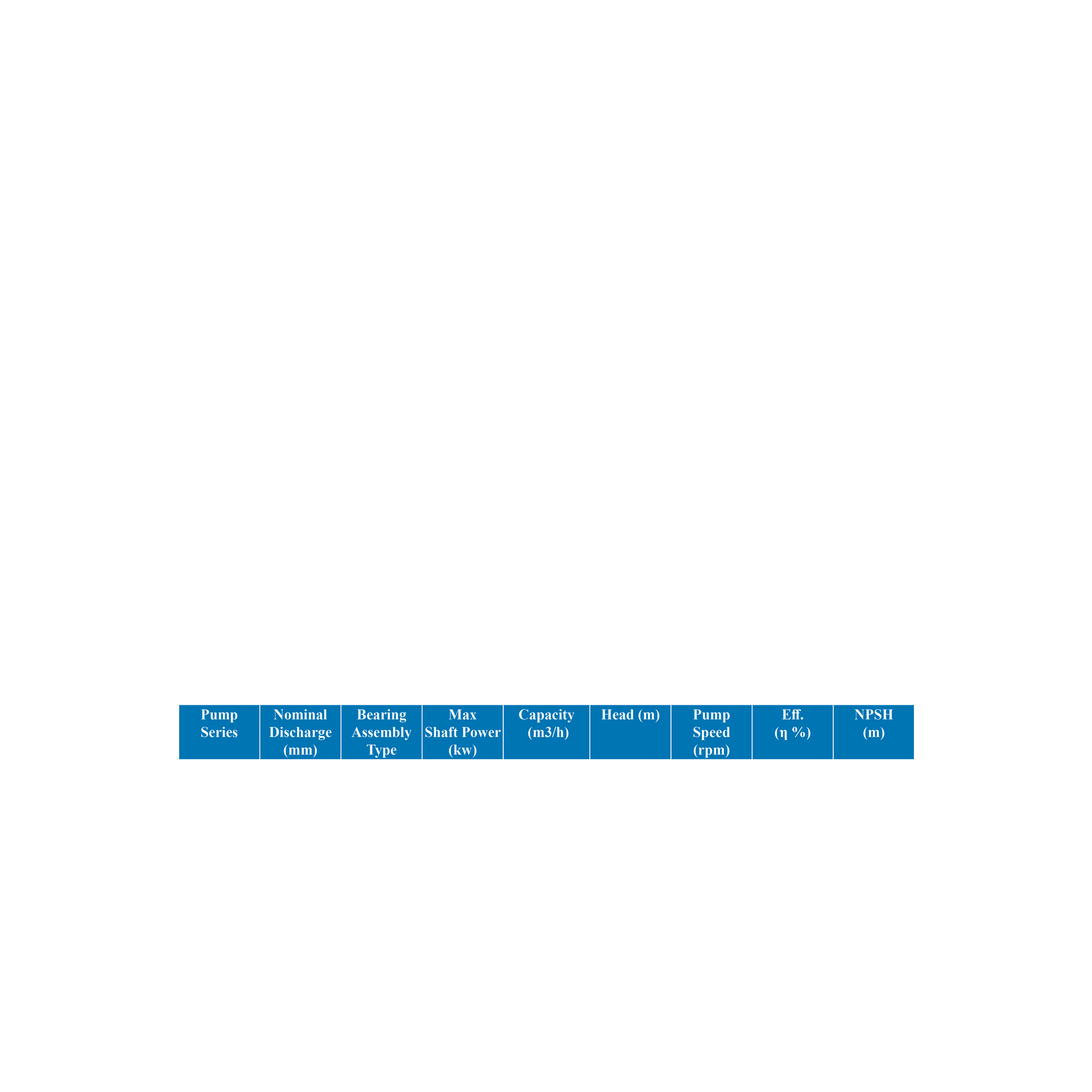

Specifiche:

- Size range (discharge) 600 mm to 1000 mm

- Capacities to 15 000 m3/hr

- Heads to 35 m

Applicazioni tipiche:

- FGD-desolforazione dei fumi

Estrazione di roccia dura

- Mine Dewatering

- Mill Discharge

- Concentrator

- Agglomerators

- Tailings

Lavorazione Minerale

- Lavaggio del carbone Fanghi di acido fosforico Separazione della sabbia

Industrial Processing

- Industria dello zuccheroProcesso chimicoCarta di cellulosaDesolforazione del gas combustibile

Informazioni sul problema della tecnica della pompa dei liquami, selezione, richiesta, non esitate a contattarci.